Table Type Shot Blaster

Updated: August 30, 2025

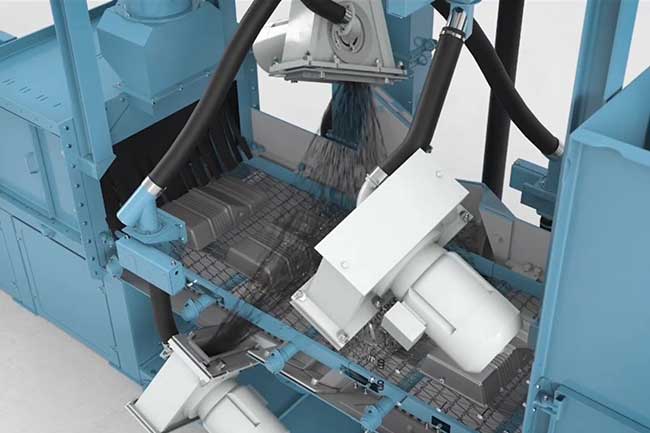

BlastKing Table Blast Machines offer a blend of superior design and robust construction, providing a fully integrated table system capable of handling larger and/or more delicate castings.

Table of Content

1. What Are The Rotary Table Shot Blasting Machines Used For?

BlastKing’s Rotary Table Shot Blast Machines offer unmatched flexibility for shot blast operations. Whether you’re cleaning welded structures and fabrications, deflashing castings, or shot peening dynamically stressed components, our Rotary Table Shot Blast Machine can significantly reduce production time.

These machines are particularly suitable for fragile parts and scenarios where part-on-part impingement is not acceptable. The table systems are ideal for parts that require gentle treatment and are not suitable for tumbling. Our standard table blast machines range from 48 inches to 84 inches in diameter, with options available for larger machines if needed. Crane slots can be added as an option to facilitate safe loading and unloading.

Revolutionize Your Manufacturing Efficiency with Our Table Shot Blaster Powerhouse!

Feel the need for speed in your manufacturing?

Our table shot blasting marvel significantly boosts production efficiency by reducing cycle times and increasing overall throughput.

Call us today at +86 135 8931 7685

2. BlastKing Offers a Wide Range of Table Type Blasting Machines

Rotary table blast machines, satellite table blast machines, and double-door swing blast machines are well-suited for processing larger workpieces with complex structures. They enable precise and reliable blasting of individual components in one-piece flows within chambers, separated segments, or on satellites.

To minimize idle time resulting from individual part processing, some systems allow for simultaneous loading and unloading of workpieces in a separate area while others are being blasted in the chamber. This process advantage is offered by systems like the satellite table blast machine and the double-door swing table blast machine. These systems can operate independently or be integrated into production lines, depending on the system type.

They are commonly used for shot peening, deburring, cleaning, roughening, and homogenizing surfaces.

3. Working Video

4. FAQs (Frequently Asked Questions)

Q1: How Do Table Blasting Machines Work?

In our table-type blasting machines, parts are strategically loaded onto a rotating table, designed to facilitate the seamless distribution of abrasive media. This rotating table is powered by a motor, offering adjustable speeds to ensure optimal exposure to the blast stream, thereby enhancing the efficiency of the blasting process.

Depending on the specific configuration of the machine, the rotating table may be positioned inside the blasting chamber for direct access, mounted on the product loading door to facilitate easier loading and unloading with lift trucks and hoists, or situated on a rail cart that smoothly slides in and out of the blasting area, particularly on larger machines where maneuverability is crucial.

As the parts rotate on the motorized table, they undergo thorough exposure to the abrasive media propelled by our ORICA blast wheels. These blast wheels, available in a range of power options from 5.5 to 30 kW, deliver high-performance shot blasting, ensuring efficient and precise treatment of the workpieces, ultimately resulting in swift and satisfactory outcomes.

Q2: How Do The Table Shot Blasters Handle Heavier Parts?

To accommodate the handling of heavier parts, BlastKing offers a variety of configurations tailored to meet diverse operational requirements:

-

Wide opening doors with enclosed roofs and crane slots provide ample space for loading and unloading parts using a hoist or lift truck, ensuring efficient handling of heavy components.

-

Tables mounted on doors that slide out of the machine enable seamless loading of parts using material handling devices, optimizing accessibility and workflow efficiency.

-

Dual swing tables equipped with two self-sealing doors and a table on each side allow for simultaneous shot blasting of one set of parts while loading or unloading another set on the adjacent table, streamlining the processing of multiple workpieces.

-

Tables mounted on rails that slide in and out of the machine, combined with roll-up doors, offer a robust solution for loading very heavy and oversized parts directly within the blasting area, ensuring maximum convenience and operational flexibility.

The configuration of our machines is fully customizable to meet the specific needs of our customers. Factors such as the number and placement of blast wheels, horsepower, machine size, table diameter, and frequency regulation of blast wheels are all carefully considered and tailored to the unique requirements of each application, ensuring optimal performance and productivity.

-

Q3: How Does the Table Blaster Reclaim the Abrasive Media?

Following the blasting process, residual abrasive media accumulates at the bottom of the blasting chamber, where it is efficiently managed through a series of advanced handling systems. Screw conveyors and a bucket elevator facilitate the seamless transfer of the abrasive media to an automatic media cleaner, ensuring thorough cleaning and recycling of the abrasive material.

The abrasive reclaimer plays a crucial role in maintaining the quality and consistency of the blasting process by continuously handling and recycling the abrasive media based on particle size. This meticulous process guarantees optimal performance and ensures that the abrasive media remains in pristine condition for future use.

To meet the stringent requirements of various applications, additional precision-enhancing features can be integrated into the system. Magnetic and/or vibratory particle separators are valuable additions that enable precise sorting of the abrasive shots based on their size and density. This level of precision ensures that only the highest quality abrasive media is utilized, resulting in superior blasting results and enhanced operational efficiency.

Q4: What Is The Standard Features of the Table Blasting Machine?

All of our shot blasting machines are outfitted with advanced features to ensure efficient and reliable operation. Each machine comes equipped with a PLC system, a user-friendly display interface, a timer for precise control, and the flexibility of both automatic and manual operating modes. Additionally, automatic start-up functionality for the blast wheels and a working-hours counter further enhance usability and convenience.

To guarantee exceptional durability and longevity, our blast wheels and the inner walls of the blasting chamber are fortified with wear-resistant shields crafted from high-quality manganese steel liners. These protective measures contribute to an extended service life, minimizing downtime and maintenance costs for our customers.

For those seeking even greater control and optimization, we offer a range of optional features to tailor the blasting process to specific needs. Blast wheels can be upgraded with a frequency drive and SMART valve technology, enabling precise adjustment of media flow for optimal results. This advanced capability ensures maximum efficiency and effectiveness in every blasting operation, allowing for superior surface preparation and treatment.

Q5: What Are the Applications of Table Blast Machines?

BlastKing’s Table Blast shot blast machines are an optimal solution for cleaning a wide range of industrial components, including automotive parts, engine components, petroleum valves and compressors, castings, fabrications, weldments, and various other items. These machines are particularly suitable for workpieces that cannot be tumbled due to their size and shape.

In our Table Blast machines, workpieces are loaded onto a stationary table or onto satellites fixed to the table before entering the blast chamber. Unlike tumbling machines, there is no movement between the workpieces, and no part-on-part contact occurs during the blasting process. This setup allows for several workpieces to be blasted or cleaned simultaneously, making it a versatile option for cleaning different types of components together.

Our Table Blast machines are available in a variety of sizes and configurations to meet the specific needs of our customers. Depending on the application requirements, our machines can be configured with single or multiple tables, as well as satellite arrangements. These configurations offer tailored solutions for various industries, including foundries, forges, automotive, heat treatment industries, and more.

Q6: What are some safety precautions to follow when operating a table type shot blasting machine?

It is crucial for operators to prioritize safety when working with shot blast machines. This includes wearing appropriate personal protective equipment (PPE) to shield against abrasive materials and dust exposure. Goggles protect the eyes from flying debris, while gloves safeguard the hands from abrasive surfaces. Respiratory masks are essential for filtering out harmful dust particles, ensuring the operator’s respiratory health.

Furthermore, operators must undergo proper training to understand the operation of the shot blast machine and adhere to safety protocols diligently. This includes familiarizing themselves with emergency procedures and understanding the potential hazards associated with operating the equipment.

Regular maintenance and inspection of the shot blast machine are also essential to identify any potential safety risks and address them promptly. By prioritizing safety measures and maintaining a proactive approach to accident prevention, operators can create a safer working environment for themselves and their colleagues.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685