H Beam Shot Blasting Machines: Boosting Efficiency and Quality in Manufacturing

Revolutionize Your Manufacturing Efficiency with Our H Beam Shot Blasting Powerhouse! Discover the secret to unparalleled precision and speed in H beam processing.

By Mathew Lee| Updated: March 11, 2024

Outline

1. An Overview of the H Beam Shot Blasting Equipment

Embracing a revolutionary approach, these shot blasting machines redefine the process of tackling corrosion, slag, and various types of corrosion prevalent in sheets, profiles, simple constructions, and support structures. Their continuous blasting capability ensures a thorough treatment, paving the way for a host of advantages.

One notable benefit lies in the expeditious and streamlined processes of cutting and welding steel semi-finished products. The machines render a clean surface, a critical factor that not only accelerates these operations but also contributes significantly to the overall efficiency of the manufacturing workflow.

Moreover, their impact is profound in enhancing the durability of surface protective coatings. Whether it’s the application of paint, enamel, or other protective layers, the clean and meticulously treated surfaces foster a superior adhesion, elevating the longevity and effectiveness of these coatings. The shot blasting machines serve as catalysts in fortifying the materials against the relentless forces of corrosion, thereby extending the life of the protective layers.

Beyond this, the machines play a pivotal role in refining the surface structure of the processed objects. By eliminating impurities and irregularities, they contribute to a smoother, more refined surface texture. This not only enhances the aesthetic appeal of the final products but also augments the overall quality and performance.

In essence, these shot blasting machines represent a paradigm shift in surface treatment, offering a holistic solution that transcends the conventional boundaries of efficiency, durability, and structural perfection in industrial applications.

Speed, Strength, Success: Transform Your H Beam Production with Our Shot Blasting Marvel!

Are delays in your production line affecting your bottom line? Our H Beam Shot Blasting Machines are your solution to eliminating bottlenecks and supercharging your output.

Unlock the potential for faster production cycles and robust, reliable results.

Call us today at +86 135 8931 7685

2. Advantages

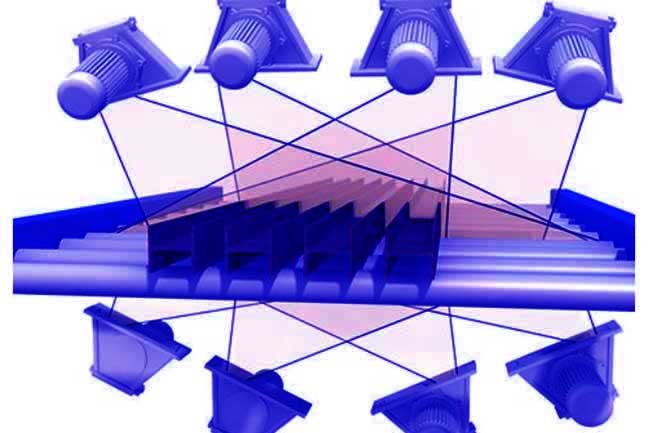

BlastKing blasting technology

BlastKing’s cutting-edge blasting solutions revolve around powerful turbines designed for unrivaled performance and cost-effectiveness. These turbines are not only robust but also economically efficient, with fewer wear parts, ensuring longevity and minimizing maintenance costs. Their high abrasive flow capacity ensures consistent and efficient blasting, making BlastKing the reliable choice for diverse applications, from large-scale industrial projects to precision-focused tasks. In essence, BlastKing redefines industry standards with a commitment to excellence, providing the strength, efficiency, and cost-effectiveness needed for impactful blasting operations.

Maximize Output, Minimize Effort: The H Beam Shot Blasting Solution You've Been Waiting For!

Are delays in your production line affecting your bottom line? Our H Beam Shot Blasting Machines are your solution to eliminating bottlenecks and supercharging your output.

Discover the secret to unparalleled precision and speed in H beam processing.

Call us today at +86 135 8931 7685

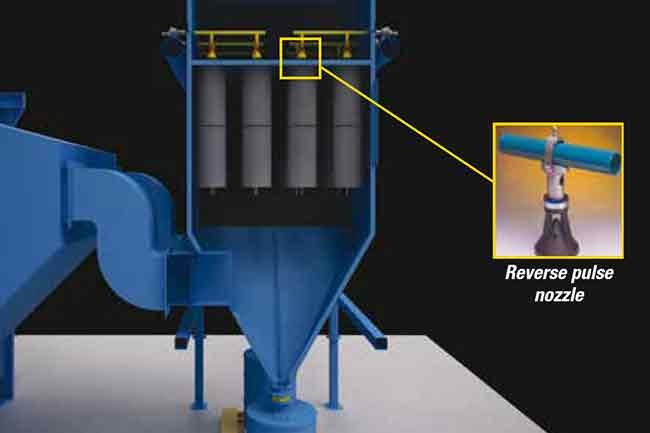

Easy to Maintain

Efficient maintenance is a cornerstone of cost-effectiveness in any industrial setting, and BlastKing roller conveyor blast machines take this commitment to the next level. Beyond the cutting-edge power unit technology and advanced filtering mechanisms, these machines boast several unique features that set them apart.

One notable aspect is the remarkable speed at which essential components can be maintained. For instance, the process of changing the blades, distributors, and control cages of the blasting turbine takes a mere 8 minutes, showcasing the machine’s user-friendly design and time-saving capabilities. Moreover, the flexibility to replace rubber curtains (sealing) outside the machine adds an extra layer of convenience, streamlining maintenance procedures for enhanced operational efficiency.

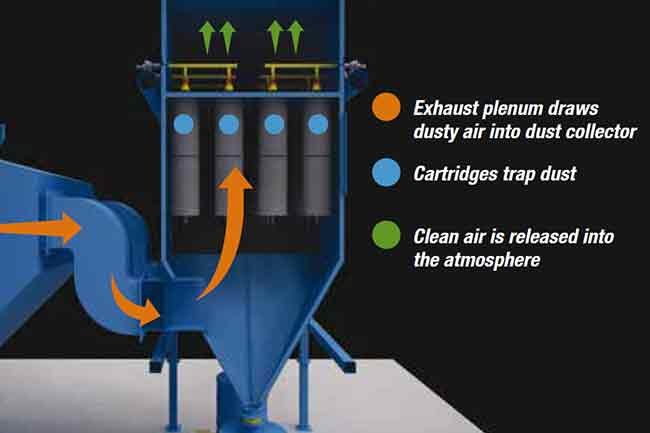

BlastKing filtering technology

Our revolutionary filtering technology stands out for its robust and high-performance capabilities. One of its standout features is the cartridge filter, offering a seamless and rapid replacement process outside the housing, thanks to a convenient pullout carrier element. This unique aspect of our cartridge filtering systems ensures not only ease of maintenance but also compatibility with older models of blasting machines, making them highly adaptable and versatile across various configurations. By incorporating this advanced filtering technology, BlastKing continues to set new standards in the industry, providing enhanced efficiency and convenience for users, regardless of the model of their blasting machines.

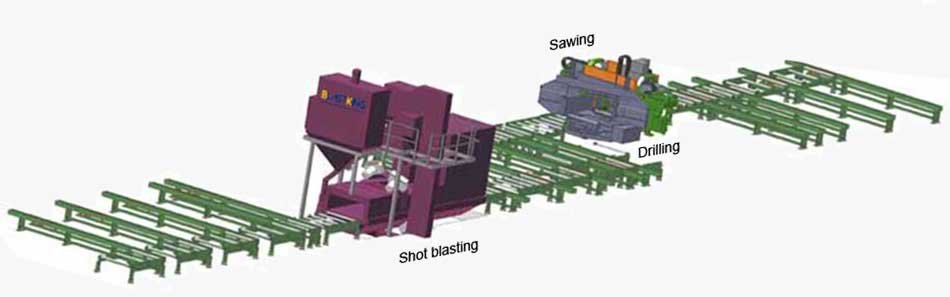

Automation

Ensuring seamless integration of the blasting machine within the facility’s logistical framework is of paramount importance. To achieve this, we incorporate innovative solutions as part of our comprehensive supply package. One such example is an automated receiver designed to monitor turbine running time and cleaning processes efficiently.

In our collaborative efforts with esteemed partners, we go beyond merely providing blasting technology. Instead, we strive to create holistic solutions, envisioning and crafting complete conservation lines. Moreover, we excel in integrating blasting technology with other essential processes, such as sawing and drilling machines. This collaborative approach not only enhances operational efficiency but also underscores our commitment to delivering tailored solutions that align with the diverse needs of our clients.

Our dedication to innovation and collaboration sets us apart, allowing us to offer not just standalone blasting machines but intricate solutions that harmonize with the overall logistics and operational setup of our clients’ facilities. Through this holistic approach, we aim to redefine industry standards, offering cutting-edge solutions that transcend traditional boundaries and pave the way for enhanced efficiency and productivity.

Safeguarding Success: Ensure Durability and Longevity in Every Blasted Product!

Fed up with constant machine breakdowns?

Invest in reliability. Our automated shot blasting machine, tailored for beams, steel plates, profiles, etc., not only enhances efficiency but also ensures the durability and longevity of your finished products.

Call us today at +86 135 8931 7685

3. Key Benefits

4. Modular Design

BlastKing’s H beam shot blasting machines, equipped with a roller conveyor system, present a versatile solution that seamlessly integrates into fully automatic preservation (paint) lines. The necessity for painting often arises to apply a corrosion protection coating on the meticulously blasted parts. Notably, there are specialized shop primers available that furnish a robust corrosion protection layer, effective for a span of up to 6 months.

The adaptability of roller conveyor shot blast/preservation lines is evident in their easy integration into existing manufacturing processes. This flexibility proves especially crucial for shipyards, where prolonged manufacturing cycles demand extended temporary corrosion protection. Beyond shipbuilding, this preservation technology is gaining traction among steel dealers, steel mills, and steel fabricators, as they increasingly recognize the value and efficacy of such preservation methods.

By offering a comprehensive solution that encompasses shot blasting and preservation processes, BlastKing ensures that industries with diverse needs, such as shipbuilding, steel manufacturing, and fabrication, can seamlessly incorporate these technologies into their operations. This not only enhances corrosion protection but also streamlines manufacturing processes, contributing to increased efficiency and durability of the treated components.

5. Working Video

6. Basic Specification

| TYPE | KB 600G | KB 1000G | KB 1500G | KB 2000G | KB 2500G | KB 3000G | |

|---|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 700 | 1100 | 1600 | 2200 | 2600 | 3300 | |

| Machine entrance height (mm) | 550 | 550 | 550 | 550 | 550 | 550 | |

| Work speed (m/min) | 0.5-2.3 | 0.5-2.4 | 0.5-2.3 | 0.5-2.5 | 0.5-3.0 | 0.5-2.5 | |

| Number of blast wheels | 4 | 4 | 4 | 4/6 | 6/8 | 6/8 | |

| Power per blast wheel (kw) | 7.5 | 7.5/11 | 11/15 | 11/15 | 11/15/18.5 | 11/15/18.5 | |

| Roller pitch (mm) | 800 | 650 | 650 | 800 | 800 | 800 | |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685

7. Service for beam shot blaster

At BlastKing, we prioritize delivering impeccable customer service, extending our commitment beyond the blasting equipment we manufacture to encompass various makes of equipment. Our comprehensive service program encompasses the following key aspects:

-

Spare Parts:

- We provide a reliable supply of high-quality spare parts, ensuring the seamless operation and longevity of your equipment.

-

Modernization and Performance Enhancement:

- Our expertise extends to the modernization and enhancement of equipment performance, incorporating innovative solutions to keep your machinery up-to-date and functioning optimally.

-

Repair and Maintenance:

- Our skilled technicians are equipped to handle repairs and conduct routine maintenance, ensuring the continued efficiency and reliability of your equipment.

-

Instruction and Training:

- We offer specialized instruction and training programs, empowering your team with the knowledge and skills required to operate and maintain the equipment effectively.

Our commitment to exceptional customer service is geared towards providing you with comprehensive support throughout the lifecycle of your equipment. Whether you require spare parts, upgrades, maintenance, or training, BlastKing is dedicated to ensuring your equipment operates at its best, promoting longevity and optimal performance.

In addition to the mentioned machines, we offer machines without notches for shot blasting bar material, pipes, gas cylinders (conical rollers), containers, and special machines according to customer requirements. The machines can be installed, together with a drying chamber, an automatic painting chamber, and a drying tunnel, in a highly productive line for applying primer.

Efficiency Redefined: Elevate Your Operations with H Beam Shot Blasting Excellence!

Are inefficiencies eating into your profits? Our H Beam Shot Blasting Excellence redefines efficiency, optimizing your operations for maximum success.

Discover the game-changing technology that takes your manufacturing capabilities to new heights.

Call us today at +86 135 8931 7685