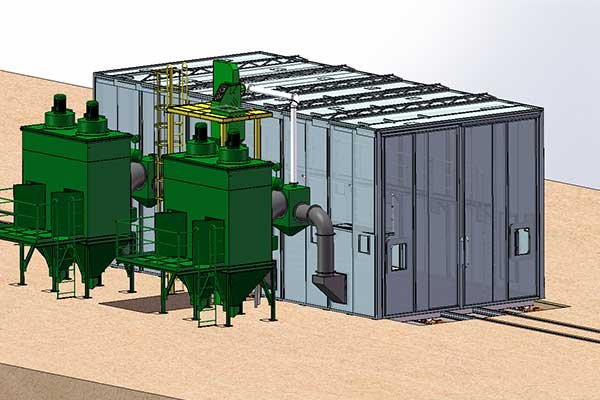

Conveyor Sand Blasting Machine

Blasting Machine Manufacturer

At Cheap Price

Both standard & custom designed blasting machines are available

At BlastKing, we specialize in advanced surface preparation solutions. Have a unique project? We’re ready to tackle it.

Our comprehensive services include consulting, concept engineering, project implementation, top-tier customer service, proven technologies, and innovative software.

For high-quality results and expert guidance, reach out to us. We’re here to turn your vision into reality.

Your Surfaces Deserve Better — Let BlastKing’s Sand Blasting Machines Do the Dirty Work

Struggling with stubborn surfaces? BlastKing has you covered. Our custom sand blasting machines—manual or automatic—make your work faster, cleaner, and more precise. From auto parts and electronics to ship hulls and furniture, we build machines that handle it all. Since 1982, BlastKing has helped professionals like you save time, cut costs, and get perfect finishes every time. Ready to make your production smoother—and maybe impress your boss while you’re at it?

Wire Mesh Belt Shot Blasting Machines

Are you looking for a reliable way to clean or strengthen metal parts? At BlastKing, we’ve been perfecting our wire mesh belt shot blasting machines since 1982. These machines provide continuous, efficient, and consistent treatment for a wide range of components.

SIEMENS PLC & HMI Control System

Reliable automation with intuitive operation for easy monitoring and control.

SIEMENS Motors

Stable, efficient power for long-term industrial use with minimal maintenance.

ZGMn13 Manganese Steel Blasting Chamber

16mm thick welded steel + 16mm thick inner liners for unmatched wear resistance.

ZGMn13 Wire Mesh Belt

High-strength, abrasion-resistant belt for continuous part handling and longevity.

Spark Arrestor Before Dust Collector

dded protection for fire safety, preventing sparks from reaching the filtration unit.

Cyclone Dust Collector + High Filter Area Unit

Dual-stage system for efficient dust separation, high air volume, and clean operation.

Our Products

When you choose BlastKing, you’re getting more than just top-notch blasting equipment. Our after-sale service team helps you install your units quickly and easily. Plus, our customer support is second to none. Need help? We’re here, ready to assist. With BlastKing, you’re never alone in your blasting projects.

Application Videos

BlastKing Since 1982

One Strong Partner at Your Side

At BlastKing, we go the extra mile with the largest installed base in the industry, delivering equipment and services to enhance your productivity and profitability. Our technical experts bring insights from thousands of applications across various industries to design solutions tailored to your needs. Let’s work together to achieve your operational goals efficiently!

GLOBLE INSTALLATIONS

R & D SENIOR ENGINEERS

TRAINED PROFESSIONALS

INTERNATIONAL OFFICES

Our Happy Clients From 30+ Countries

Why Choose BlastKing?

1. Decades of Expertise

At BlastKing, we’ve been around the block a few times—over 40 years, to be exact! With our decades of experience, we bring a treasure trove of know-how to every project. We get blasting technology like the back of our hand, ensuring our products are top-notch, innovative, and rock-solid reliable. So, when you choose BlastKing, you’re not just getting a product; you’re getting a legacy of expertise and a touch of ingenuity. Let’s face it, we’re the kings of blasting for a reason!

2. Innovative Solutions

At our company, we’re not just riding the wave of innovation – we’re making it! We’re always pouring our heart and soul (and a bit of our budget) into research and development. Take our dustless blasting machines, for instance. They’re the perfect blend of eco-friendly and powerhouse performance. We’re kind of like the tech wizards of the blasting world, conjuring up machines that are as kind to Mother Earth as they are tough on grime.

We’re always on the lookout for the next big thing, ensuring our customers get nothing but the best. After all, why settle for good when you can have great, right? It’s like they say, “The early bird catches the worm,” and we’re up and at ‘em before the rooster even thinks about crowing!

3. Comprehensive Product Range

Looking for a shot blasting machine that can handle the toughest industrial tasks? Or maybe you need a horizontal movable shot blaster that’s as flexible as a gymnast? Either way, BlastKing has got your back! We’ve got a wide range of products to suit every need. So whether you’re tackling a mammoth project or something a bit more nimble, you’ll find just what you’re looking for with us. Let’s get you blasting away in no time!

4. Exceptional Customer Support

At BlastKing, we don’t just shake hands and wave goodbye after you’ve made a purchase. Oh no, our journey together is just getting started! Think of us as your trusty sidekick, always ready to jump in and lend a hand whenever you need it.

Got a question about maintenance? We’ve got the answers. Need some technical wizardry? Our team is on it. Want to learn the ins and outs of your new equipment? Our training programs have got you covered.

And don’t worry, our dedicated customer service team is always just a call away, eager to help you squeeze every last drop of awesomeness out of your BlastKing gear. So, let’s keep the conversation going and make sure you’re getting the royal treatment you deserve!

5. Proven Track Record

You know what they say: the proof is in the pudding! At BlastKing, we’ve got a long list of happy customers from all sorts of industries who can vouch for us. Our track record? It speaks volumes.

From small businesses to global giants, companies all over the world put their trust in BlastKing for their blasting needs. Why? Because we consistently deliver top-notch products and services, every single time. So, whether you’re a seasoned pro or new to the blasting game, rest assured—we’ve got your back!

Call us today at +86 135 8931 7685

FAQs - Frequently Asked Questions

Q.1 What is shot blasting?

Shot blasting is like a high-powered scrub for metal surfaces. Imagine your car getting a top-notch detail. That’s what shot blasting does for metal—cleaning, strengthening, and polishing it to perfection.

How It Works

Picture this: a blasting machine, a chamber, and a recovery system all working together. Steel shot or grit is shot at the metal surface, removing rust and grime. It’s like exfoliating, but for steel!

Applications

Shot blasting is a go-to in various industries. It preps surfaces for painting in manufacturing, cleans engine parts in automotive work, and readies steel structures in construction.

Benefits

- Surface Prep: Perfect for getting surfaces ready for a new coat of paint.

- Durability: Makes metal parts last longer.

- Cost-Effective: Saves time and reduces manual labor.

Equipment

Key components include the blast wheel, blast cabinet, and recycling system. The blast wheel hurls the abrasive media, while the blast cabinet keeps the mess contained. The recycling system cleans and reuses the abrasive material.

Types of Machines

- Wheel Blasters: Ideal for large-scale operations.

- Air Blasters: Great for precise cleaning tasks.

Safety Tips

Always wear protective gear, ensure good ventilation, and maintain your equipment.

Conclusion

Shot blasting is a behind-the-scenes hero in many industries. It’s the ultimate makeover for metal, making it smoother, stronger, and more durable. So, the next time you see a polished piece of metal, you’ll know the secret behind its shine!

Q.2 What is shot blasting machine?

A shot blasting machine is a mechanical method of propelling abrasive using a centrifugal wheel to remove surface and other impurities from the surface of steel applications. General, blasting prior to finishing serves three primary purposes:

- It cleans and descales surfaces

- Adds texture to enhance paint adhesion

- Properly reduces maintenance costs by increasing coating life

Q.3 What is sandblasting?

Sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface and shape a surface, or remove the surface contaminants.

Q.4 What Is the Purpose of Sandblasting?

Sandblasting can thoroughly clean and prepare a surface for painting. This process is for spraying sand at a high velocity toward the intended surface remove stubborn dirt, grime, and other matter. Meanwhile, it is also an ideal technique for concrete, brick, stucco, and other surfaces.

Q.5 what are the useful effects of Shot Blasting Machines’ Blasting?

Shot blasting machines’ blasting benefits are as follows:- It provides higher production rates, wider abrasive selection and better blast pattern accuracy.

- The finished surface obtained is absolutely free from chemical deposits, scales, and dust content.

- Shot blasting facilitates the formation of a permanent bond between the protective coat (zinc, paint, or epoxy) and the shot blasted surface. It also helps to detect surface faults or defects.

- It eliminates the usage of non-ecofriendly and harsh chemicals.

- Increases longevity and durability of protective surface coats as it adheres better to the shot blast cleaned and scale-free surface.

Q.6 What is difference between shot blasting and sandblasting?

Sandblasting and shot blasting both are processes that are being utilized in mechanical surface cleaning. Many industries that use metal apply these methods in daily practices for removing of corrosion, paint, and other films and preparing the surface for coating. In both methods, cast-iron work is also blasted to remove old paint layers. But the differences between both processes are only for principle and application types.

Q.7 What type of material does the abrasive consist of?

For turbine wheel shot blasting, the abrasive material used consists of 90% steel due to the high energy with which the abrasive is ejected onto the workpiece surfaces. Round cast steel shot material ranging from 0.8 to 1.5 mm in diameter is often used. Angular cast steel shot material or sections of wire mesh can also be used. The required surface finish determines what type of abrasive should be used.

Q.8 How do you clean the abrasive?

A cascade wind sifter is used for most applications. The abrasive is distributed and guided so that it forms a fine mist/veil. This is achieved by having the abrasive trickle over a wide edge. A cartridge filter unit generates a flow of air through the mist of abrasive material. Fines such as broken grain and dust are thus removed from the abrasive and separated via an impact separator and/or filter cartridges. In special cases like in foundries, for example, a magnetic sifter is fitted upstream of a cascade sifter and used to separate the abrasive metal material from the sand and discharge it.

Q.9 To where does BlastKing deliver?

BlastKing delivers worldwide to over 50 countries on all continents. BlastKing’s customers can be found in a wide range of industrial sectors. This includes foundries, forges, the machine-building sector, and the auto industry, for example.