How BlastKing Construction Shot Blasting Machines Are Changing the Game

Updated: March 28, 2025

Discover how BlastKing shot blasting machines are revolutionizing construction projects by delivering faster, cleaner, and more efficient surface preparation for concrete, steel, and beyond—making tough jobs easier and results more durable.

Outline

1. Introduction

Surface prep. We know it’s not the flashiest part of construction, but it’s a job that needs to be done right. BlastKing shot blasting machines make it a whole lot easier, faster, and, honestly, a little more satisfying. Whether you’re getting rid of rust or prepping a surface for painting or welding, these machines have got your back.

In this article, we’ll break down how BlastKing shot blasting machines work and why they’re a must-have for anyone serious about getting their projects done right and on time.

2. What’s Construction Shot Blasting?

Picture this: a high-speed cleaning method that uses tiny steel shots or grit to blast away dirt, rust, and old coatings. BlastKing machines fire these little particles at surfaces to clean them up in record time. Concrete, steel—you name it, these machines handle it.

Shot blasting gives you a smooth, prepped surface ready for whatever comes next—coating, painting, welding, or just looking sharp.

Say Goodbye to Manual Labor - Embrace Automation!

Manual labor can be a real time-drainer and often leads to mistakes. That’s where our automated shot blasters come in. They take the guesswork out of the equation, delivering consistent results every time. Plus, they free up your team to focus on more important tasks. It’s like having a reliable coworker who never takes a break!

Call us today at +86 135 8931 7685

3. What’s Inside a Construction Shot Blasting Machine?

Let’s pop the hood and take a quick look inside a BlastKing machine:

- Blast Wheel: This part’s the powerhouse. It hurls the steel shots or grit at high speed.

- Abrasive Media: These are the steel shots or grit that do the heavy lifting, cleaning up your surfaces.

- Media Recovery System: This is your budget-saver. It collects the used abrasive material, cleans it, and sends it back out again so you can reuse it.

- Dust Control System: Keeps the worksite safe and clean by trapping all the dust before it becomes a problem.

These machines aren’t just about brute force—they’ve got smart systems to make your life easier.

4. Key Benefits

Tailored Solutions for Every Industry!

Worried a one-size-fits-all solution won’t cut it for your industry? No problem! We offer customized shot blasting solutions for automotive, aerospace, construction, and more. Our experts will work with you to design a system that fits your needs like a glove, ensuring maximum effectiveness. Let’s make sure your blasting process is spot-on!

Call us today at +86 135 8931 7685

5. Introducing the X-Type Construction Blasting Machine: Your Go-To Solution!

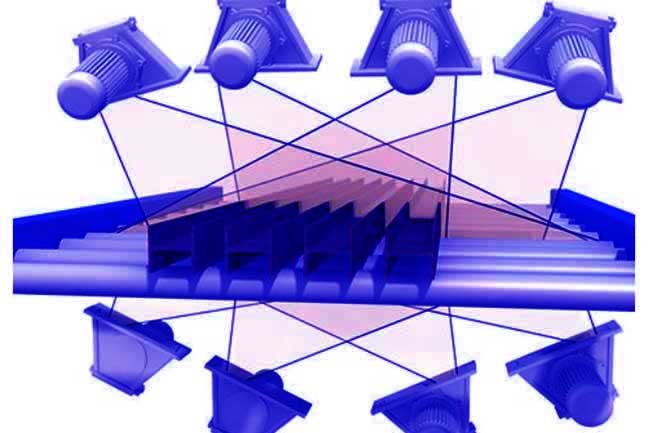

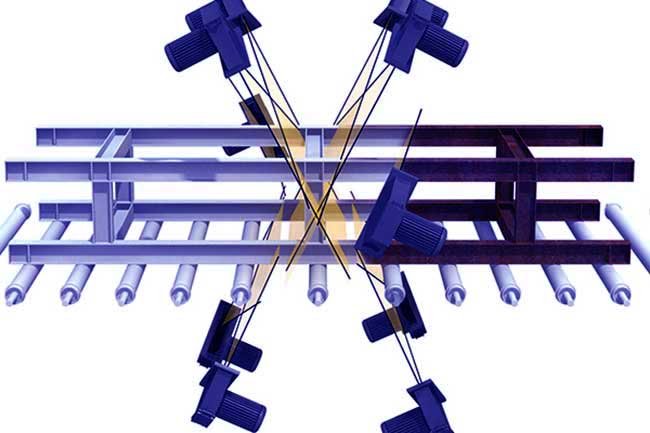

Let’s face it: when it comes to surface preparation, nobody wants to deal with rusty, uneven materials. Enter the X-Type construction blasting machine—your smart cousin in the world of blasting! Unlike the Type G and Type HD models, this beauty has angled turbines that perfectly match the material’s movement. It’s like having the perfect angle while washing your car—cleaning just got a whole lot easier!

These turbines are arranged symmetrically, ensuring that every inch of your material gets the same level of attention. It’s all about even coverage, and thanks to 3D computer simulations, you can trust that every blast is spot-on. Think of it as a spa day for your materials—refreshing and rejuvenating, minus the fluff!

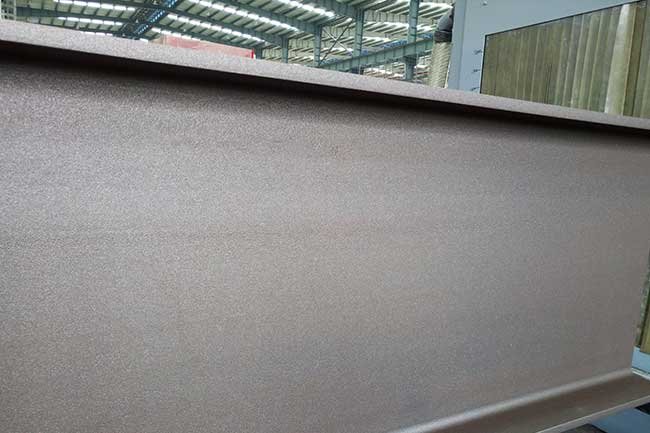

This machine isn’t just a pretty face. It’s designed for fabrication, construction, and PEB beams, and it’s a multi-functional champ. It tackles rust, weld slag, and oxidized skin with ease. The result? A uniform metallic luster that boosts the quality of steel coatings and improves anti-corrosion effects.

But that’s not all! The X-Type can also pull double duty as a “Universal Blasting Machine.” It works wonders on sheet metal, profiles, and welded constructions. Whatever your project demands, this machine is ready to rise to the occasion.

So, if you’re looking to up your game in surface preparation, the X-Type construction blasting machine is your answer. It’s smart, efficient, and ready to tackle any challenge. Why settle for second best when you can have the X-Type doing the heavy lifting?

6. Working Video

7. Basic Specification

| Type | KB 7.5/2.5X | KB 7.5/5X | KB 15/5X | KB 15/10X | KB 20/15X | KB 25/15X | KB 30/15X | KB 30/20X |

|---|---|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 850 | 850 | 1600 | 1600 | 2100 | 2600 | 3100 | 3100 |

| Machine entrance height (mm) | 300 | 550 | 550 | 1050 | 1550 | 1550 | 1600 | 2100 |

| Work speed (m/min) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Number of blast wheels | 4 | 4 | 4 | 4/6 | 6/8 | 6/8 | 8/10 | 14/16/18 |

| Power per blast wheel (kW) | 7.5 | 7.5/11 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15/18.5 |

| Roller pitch (mm) | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

8. Where Can You Use Shot Blasting?

BlastKing shot blasting machines aren’t picky—they can handle a wide range of construction tasks. Here’s a taste of what they can do:

- Concrete Prep: Getting concrete ready for a new coat of something shiny? Shot blasting will clean it up in no time.

- Steel Rust Removal: Have some rusted steel beams or metal surfaces? A few passes through the machine, and they’re rust-free and ready for action.

- Surface Texturing: Shot blasting adds just enough texture to make sure coatings and paints stick like glue.

These machines do the dirty work so you can focus on the big picture.

9. How Shot Blasting Preps Concrete?

Imagine you’ve got a concrete floor covered in grime and old paint. You need it spotless for a new epoxy coat. Enter BlastKing. The machine rips through that old junk, leaving the surface clean and slightly rough, perfect for a strong bond with the new coating. You’re left with a floor that looks and performs like new.

Eco-Friendly Solutions for a Sustainable Future!

Is environmental impact a major concern for your business? Our eco-friendly floor shot blasters are designed to meet the highest environmental standards, reducing your carbon footprint while maintaining exceptional performance. Join us in our commitment to sustainability.

Call us today at +86 135 8931 7685

10. Real-World Success with BlastKing

Here’s how BlastKing shot blasting machines are making life easier in real-world construction:

- Bridge Restoration: Cleaning up concrete bridges for new epoxy coatings, fast.

- High-Rise Steel: Removing rust from steel beams, ensuring perfect prep for painting and welding.

- Highways: Prepping asphalt for sealants, boosting road durability.

These projects show how BlastKing machines deliver results that last.

to make your life easier.

11. FAQs (Frequently Asked Questions)

Q1: What is shot blasting, and how does it work?

Shot blasting is like giving your metal parts a fresh haircut—it clears away all the rust, paint, and grime to reveal a clean, smooth surface underneath. Whether you’re getting parts ready for a new paint job or toughening them up before welding, shot blasting gets the job done right.

Here’s the gist: the machine fires steel pellets or grit at high speeds, kind of like throwing tiny metal hail at your workpiece. These particles hit the surface and knock off all the junk, leaving it nice and clean. It’s the industrial version of sandblasting, but with a lot more muscle.

The machine has three main parts: the blasting chamber (where the magic happens), the media recovery system (which scoops up and recycles the pellets), and a dust collector (so you’re not breathing in all that debris). It’s efficient, cost-effective, and keeps things tidy.

Shot blasting works wonders on big, flat surfaces and even on those hard-to-reach nooks and crannies. It’s like having a dependable sidekick to get your metal parts prepped and ready for whatever comes next—whether that’s welding, painting, or just looking sharp!

Q2: Can BlastKing shot blasting machines handle both concrete and steel?

Yes, BlastKing shot blasting machines can handle both concrete and steel, no problem. These machines are like the multitools of surface prep—whether you’re cleaning up rusty steel or roughing up concrete for a new finish, they’ve got you covered.

For steel, it’s a full-on deep clean. The machine fires high-speed steel shot or grit at the surface, knocking off rust, paint, and whatever else is hanging around. By the time it’s done, the surface is smooth and ready for painting, coating, or welding.

For concrete, it’s all about getting that perfect texture. The machine roughens up the surface just right, making sure it’s prepped for any coatings or sealants you want to throw on. Think of it as creating a surface that holds onto whatever’s coming next, like Velcro for coatings.

The best part? You don’t need a different machine for each job. Just change up the abrasive media—steel gets the tougher treatment with steel shot, while concrete uses a softer abrasive.

In short, BlastKing machines are like your go-to tool in the workshop: reliable, adaptable, and ready to handle whatever surface prep you throw at them.

Q3: Is shot blasting eco-friendly?

Shot blasting is like giving your metal a serious scrubbing, but with zero chemicals and way less mess. It’s the eco-friendly version of a deep clean that doesn’t leave a trail of waste behind. Instead of using harsh stuff, it fires recyclable steel shot or grit at the surface to knock off all the grime—then reuses the same media again and again. Kind of like getting a second (and third) life out of your tools!

And let’s be honest, no one likes a dust cloud hanging around. That’s why these machines come with dust collection systems that keep the air clear and your workspace a lot more comfortable.

Plus, you won’t have to worry about nasty chemicals seeping into the ground or water. Shot blasting skips all that, sticking to the basics—just good old-fashioned mechanical cleaning. And while it does take some energy to run, newer machines are pretty efficient, so you’re not blowing up your power bill.

In short, shot blasting is the cleaner, greener way to prep your metal parts without all the hassle and mess. It’s tough on rust but easy on the planet.

Q4: How does shot blasting improve surface durability?

Shot blasting is like giving your metal surfaces a workout. Not only does it strip away rust and grime, but it toughens things up, too. Think of it as a two-for-one deal: cleaning and strengthening in one go.

Here’s how it works: high-speed steel shot or grit slams into the surface, knocking off all the unwanted layers. But there’s more—those tiny impacts create little dents that put the surface under stress, in a good way. It’s like hitting the gym for your metal. Those dents make the material more durable, helping it resist cracking, wear, and fatigue down the road.

And let’s not forget, shot blasting also makes sure paint or coatings stick better by smoothing out rough spots. So, your material not only lasts longer but looks better, too.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685

12. Conclusion

BlastKing shot blasting machines are changing the way construction surfaces get prepped. They save time, reduce labor, and ensure better quality finishes on steel, concrete, and more. Whether you’re dealing with rust, dirt, or old coatings, these machines make it easier to get your surfaces ready for the next step. When your project demands quality and speed, BlastKing machines are your go-to solution.