Wire Rod Shot Blasting Machines

Do you find your current wire rod processing causing unnecessary delays in your production line? Our shot blasting machines eliminate downtime, ensuring a streamlined and efficient manufacturing process.

Table of Contents

1. What is A Wire Rod Shot Blasting Machine?

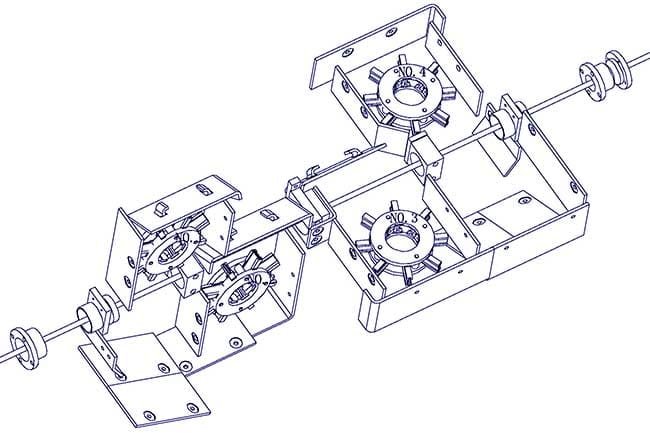

A Wire Rod Shot Blasting Machine is a specialized industrial equipment tailored for the surface preparation of wire rods. This machine employs a shot blasting process to effectively clean, descale, and improve the surface quality of wire rods in preparation for subsequent manufacturing processes.

Available in configurations with 3, 4, or 6 wheels, single- or multistrand longitudinal blast machines are designed to meet diverse capacity requirements. They can be effectively adapted to accommodate changing product runs. These shot blast machines are easily integrated into modern drawing lines, operating at speeds of up to 240m/min, or can function independently as stand-alone machines for autonomous finishing.

2. Features

- Proven ORICA® double-disc blast wheels with the linear layout

- Various numbers of wheels are possible

- Remote control adjustment of abrasive throughput to meet different production conditions

- Blast housing made of wear-resistant manganese steel

- From stand-alone machines to integrated solutions

- Maximum energy utilization by use of adjustable abrasive stream guide plates

3. Applications

- Descaling of round, square, hexagonal or flat wire, wire rod, welding rod, and bars

- Single-strand Machines or Multi-strand machines are available

4. Key Benefits

5. How Wire Rod Shot Blasting Machines Work

At the heart of these machines is a sophisticated blasting process that entails the high-velocity ejection of abrasive media. This abrasive action adeptly eliminates rust, scale, and contaminants from the surface of wire rods, ensuring they are left clean and prepared for subsequent processing. The components of a Wire Rod Shot Blasting Machine work cohesively to achieve this, with abrasive media playing a pivotal role in enhancing the overall efficiency of the process.

6. Working Video

7. Basic Specification

| Machine Model | FL-3-38 | FL-3-55 | FL-4-55 | FL-6-55 |

|---|---|---|---|---|

| Max. diameter (mm) | 38 | 55 | 55 | 55 |

| Wheel number | 3 | 3 | 4 | 6 |

| Wheel power(kw) | 22 | 30/37 | 30/37 | 30 |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

8. Conclusion

In conclusion, Wire Rod Shot Blasting Machines have emerged as indispensable tools in the industrial landscape. Their ability to transform surface preparation processes, enhance efficiency, and contribute to sustainable practices makes them a cornerstone in various industries. Businesses seeking to optimize their manufacturing processes can undoubtedly benefit from the transformative power of Wire Rod Shot Blasting.

Tired of Inconsistent Quality?

Say goodbye to variations in steel quality. Our advanced shot blasting technology guarantees a uniform surface finish, elevating your steel products to meet the highest standards.

Call us today at +86 135 8931 7685

FAQs (Frequently Asked Questions)

Q1: What is Airblast Equipment used for?

Airblast equipment stands at the forefront of cutting-edge technology in surface preparation and cleaning applications. Specifically engineered for precision and efficiency, these machines utilize the force of compressed air to propel abrasive media onto target surfaces. The process involves the removal of impurities, contaminants, and unwanted coatings, creating an ideal foundation for subsequent treatments or coatings. The versatility of airblast equipment makes it a go-to solution across diverse industries, ensuring optimal results in enhancing surface quality and promoting superior coating adhesion. Whether it’s metal, wood, concrete, or even delicate materials like glass, airblast equipment offers a customizable approach, allowing adjustments based on the abrasive media and equipment settings. The innovation and reliability embedded in airblast technology make it an indispensable tool for achieving impeccable surface finishes in industrial and manufacturing settings.

Q2: How does airblast equipment improve surface preparation?

Airblast machines play a crucial role in industrial surface preparation by efficiently removing impurities from various materials. Through the forceful projection of abrasive media propelled by compressed air, these machines ensure a thorough cleaning process. This meticulous surface preparation not only eliminates contaminants such as rust, scale, or old coatings but also enhances the adhesion of subsequent coatings, promoting a longer-lasting and more durable finish.

By employing cutting-edge technology, airblast machines offer a precise and controlled approach to surface treatment. The adjustable parameters, including air pressure, nozzle size, and choice of abrasive media, allow for customization based on the specific requirements of different materials and applications. This versatility makes airblast equipment a go-to solution in industries ranging from manufacturing and construction to automotive and aerospace.

The result is not just a visually improved surface but one that is optimally prepared for the application of coatings or other finishing processes. The enhanced adhesion achieved through airblast operations ensures that coatings bond securely to the material, providing superior protection against corrosion and wear. Overall, airblast machines contribute significantly to the quality, longevity, and performance of finished products across various industrial sectors.

Q3: What surfaces can airblast equipment be used on?

Airblast equipment, renowned for its versatility, is an indispensable tool in various industries, offering unparalleled capabilities in surface preparation and cleaning. Designed to accommodate a wide array of materials, this equipment exhibits remarkable adaptability, ensuring optimal performance across diverse surfaces.

Whether you are working with robust metal components, intricate wooden structures, solid concrete surfaces, or delicate materials like glass, airblast equipment can be fine-tuned to meet the specific demands of each application. The key to its adaptability lies in the careful selection of abrasive media and the precise adjustment of equipment settings.

For metal surfaces, airblast equipment can efficiently remove rust, scale, and contaminants, preparing the substrate for coatings or other treatments. In woodworking applications, it aids in refining surfaces, ensuring a smooth finish for subsequent processes. In the realm of concrete, airblast technology proves invaluable for cleaning and preparing surfaces, addressing challenges unique to this material. Even when delicacy is paramount, as in the case of glass, airblast equipment can be configured to provide a gentle yet effective touch.

This versatility is a testament to the engineering sophistication of airblast systems, making them indispensable across a spectrum of industries. The ability to tailor abrasive media and equipment settings ensures that the same equipment can be seamlessly integrated into diverse workflows, meeting the ever-evolving demands of modern industrial applications.

Q4: What types of abrasive media can be used with airblast equipment?

A diverse array of abrasive media is employed in airblast and wet blasting equipment, each serving unique purposes based on application requirements and the desired finish. Among the commonly utilized abrasive media are options such as sand, known for its versatility and cost-effectiveness, aluminum oxide, renowned for its hardness and recyclability, steel shot, prized for its durability and ability to impart a peening effect, glass beads, preferred for delicate surfaces and achieving a smooth finish, and garnet, recognized for its natural hardness and suitability in precision applications. The selection process involves careful consideration of factors such as the type of surface being treated, the specific finish desired, and the overall goals of the blasting operation. By choosing the appropriate abrasive media, operators can optimize the effectiveness of the blasting process and achieve superior results across a range of industrial applications.

Q5: Can airblast equipment be customized for specific applications?

Yes, indeed. Many reputable manufacturers recognize the diverse needs of industries and offer extensive customization options for airblast machines. The ability to tailor these machines to specific application requirements is a testament to their commitment to meeting the unique demands of various users. This customization extends beyond the basics, allowing adjustments to crucial blast parameters and features.

Whether it’s adapting the pressure, adjusting nozzle sizes, or fine-tuning other operational aspects, these tailored solutions cater to the nuanced requirements of different applications. Manufacturers collaborate closely with users, comprehensively understanding their workflow, objectives, and challenges. This collaborative approach ensures that the airblast machines not only meet but exceed expectations, delivering optimal performance for specific tasks.

Moreover, the flexibility in customization extends to the choice of abrasive media, accommodating the varied needs of industries. Different applications may demand specific abrasive materials, and manufacturers can provide guidance on selecting the most suitable media based on factors like material composition, desired finish, and overall project goals.

In essence, the commitment to customization empowers users to have airblast machines perfectly aligned with their operational needs. This personalized approach not only enhances the efficiency and effectiveness of the equipment but also contributes to the overall success of diverse industrial applications.

Q6: Is wet blasting a suitable alternative?

Wet blasting, a cutting-edge surface preparation technique, is characterized by the judicious combination of water with abrasive media, resulting in a highly effective and environmentally conscious process. By integrating water into the abrasive stream, this method not only minimizes dust generation but also imparts a more delicate treatment to surfaces. This innovative approach is particularly well-suited for applications where dust reduction is of paramount importance, aligning with stringent environmental and safety standards. The synergistic effect of water and abrasive media enhances the efficiency of the blasting process while providing a versatile solution across diverse industrial contexts.