Hanger Shot Blasting Machine: Boost Your Productivity

Updated: August 31, 2025

Tired of rust and grime? The BlastKing Hanger Shot Blasting Machine’s got your back. Get faster, cleaner metal prep and boost your productivity today!

Outline

1. Introduction

We all know that cleaning and prepping metal surfaces isn’t anyone’s favorite task, but it’s got to be done. That’s where the hanger shot blasting machine comes in, saving the day like a trusty tool that gets the job done without the headache. Specifically, the BlastKing Hanger Shot Blasting Machine—a machine designed to make surface preparation faster, easier, and way more efficient. If you’re looking for something to boost productivity while cutting down on time, you’re in the right place.

Let’s dive in and see how this machine can give your business the edge.

2. What Is a Hanger Shot Blasting Machine?

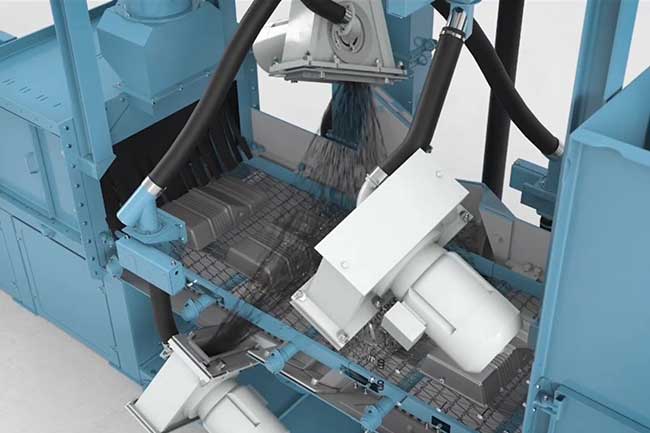

Think of a hanger shot blasting machine as a high-powered cleaner for metal parts. It uses abrasive material (think tiny, tough particles) to blast away rust, grime, and scale. The machine hangs your metal pieces on hooks, then shoots abrasives at them, covering every surface.

The BlastKing version of this machine is built for heavy-duty use. Whether your parts are big, small, or oddly shaped, it can handle them all. Plus, it’s smart—it recycles the abrasives automatically, so you’re not constantly refilling. It’s kind of like having a car that refuels itself—no pit stops.

Tired of Slow, Costly Metal Cleaning Processes? Your Metal Parts Deserve Better!

Why wait? Give your team (and yourself) a break. Request a demo or get a quote today, and see how the BlastKing Hanger Shot Blasting Machine can change the way you do business.

Call us today at +86 135 8931 7685

3. Types of Hanger Blasting Machines

Shot blasting machines come in two main types: Batch Type and Continuous Type. Both get the job done, but they’ve got their own tricks.

Batch Type Hanger Blast Machines

These machines work one batch at a time. You load the parts in, let them rotate, blast away the rust or scale, then unload them. Simple. They’re perfect for parts that need a little extra care—ones that could crack under too much force. If you’re handling anything from small to large parts for desanding, decoring, or descaling, Batch Type is your friend.

Popular examples:

- Spinner-Hanger blast machines

- HB Overhead Rail blast machines

- Overhead Rail machines for heavy-duty jobs

Continuous Type Hanger Shot Blasters

If you’ve got a steady flow of parts moving through your line, Continuous Type is what you need. Think of it like a monorail for your parts, keeping things moving without a break. It speeds up production, saves floor space, and cuts down on downtime. The result? Lower costs and a smoother operation.

Popular models:

- Continuous Overhead Rail blast machines

- Heavy-duty Continuous Overhead Rail machines

4. How Does It Boost Productivity?

Let’s talk results. How does this machine actually help you get more work done?

-

Speed: The BlastKing machine gets metal surfaces cleaned up fast—instead of scrubbing for hours, you’re watching the machine power through metal surfaces in minutes.

-

Consistency: Every part of the surface gets blasted evenly. No missed spots, no “I’ll get to that later” areas. Consistent results every time.

-

Less Labor: Once your parts are loaded onto the machine, you’re good to go. Your team can focus on other jobs instead of standing around managing the process.

Increasing Efficiency: Less Downtime, More Output

You know what kills productivity? Downtime. You’re ready to go, but your equipment’s not. With BlastKing, you get an automatic abrasive recovery system that keeps things running smoothly. No need for constant stops to clean out the machine—it’s all taken care of.

Call us today at +86 135 8931 7685

5. Key Benefits: More Than Just Speed

Speed is great, but what if you could have speed, quality, and versatility? With the BlastKing Hanger Shot Blasting Machine, you’re getting all three. Let’s break it down:

Accelerated Cleaning and Preparation

Blasting machines are made to clean fast. BlastKing’s hanger shot blasting machines tackle even tough grime or rust. You’re not spending hours scrubbing parts—just load them up, let the machine do its thing, and move on to the next task.

Improved Surface Quality

The whole point of blasting is to get a clean, even surface. These machines guarantee that every part of the workpiece gets the same level of attention. That means better results when you’re painting, coating, or prepping parts for further work.

Versatility in Applications

These machines handle various sizes and shapes, making them adaptable to multiple tasks.

- Automotive: Prepping parts for painting or assembly.

- Construction: Cleaning up structural components.

- Foundries: Removing sand and scale from castings.

- Shipbuilding: Prepping large, odd-shaped parts.

Basically, if it’s metal, these machines can clean it.

How Does Hanger Blasting Machines Boost Productivity?

Here’s the bottom line: The BlastKing Hanger Shot Blasting Machine is the key to faster, more reliable metal surface prep. No more endless scrubbing, no more inconsistent results, and no more wasted time. If you’re ready to boost your productivity and streamline your process, BlastKing is the way to go.

Call us today at +86 135 8931 7685

6. Choosing the Right Hanger Type Shot Blasting Machine

Considerations When Selecting a Machine

When you’re picking a hanger shot blasting machine, here’s what you need to think about:

- Size and Material of Parts: Match the machine to the kind of parts you’re working with.

- Production Volume: For smaller runs, go with batch machines. If you’ve got a ton of parts to process, continuous machines are your best bet.

- Power: Make sure the machine has enough muscle for the job.

Top Brands and Models

BlastKing makes machines that last. They offer different models suited for a variety of tasks. Whether you’re cleaning delicate parts or dealing with heavy-duty projects, there’s a machine that’ll fit.

Balancing Cost and Productivity

These machines are an investment, no doubt. But the time you save, the labor you reduce, and the productivity you gain make it worth every penny. Over time, you’ll wonder why you didn’t make the switch sooner.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685

7. FAQs (Frequently Asked Questions)

Q1: Who uses hanger shot blasting machines?

Ever wondered who puts hanger shot blasting machines to good use? Let’s explore the industries where these machines are the unsung heroes.

Automotive Industry

In the world of cars, manufacturers use these machines to clean and strengthen engine blocks and chassis parts. It’s like giving metal a fresh start before it hits the road. Without this step, vehicles might not run as smoothly—or as safely.

Structural Steel Fabrication

Building bridges or skyscrapers? Companies here rely on hanger shot blasting to remove rust and welding residue. This ensures paint and coatings stick properly, making structures durable for the long haul.

Foundries and Forging Plants

Metal parts often come out a bit rough around the edges—literally. Hanger shot blasting machines smooth out sand, scale, and burrs. Think of it as giving metal a quick makeover before the next stage.

Aerospace Industry

When crafting parts that soar through the skies, there’s no room for error. Aerospace companies use these machines to treat turbine blades and other vital components, boosting strength and extending lifespan.

Heavy Equipment Manufacturing

Manufacturers of tractors, bulldozers, and cranes clean large metal parts before painting or coating. This prep work ensures the equipment can handle tough jobs without a hitch.

Railway Sector

In the railway industry, preparing metal surfaces is crucial. Hanger shot blasting helps keep trains safe and efficient on the tracks. After all, nobody wants a train derailed by a bit of rust!

Shipbuilding and Marine Industry

Saltwater and metal aren’t exactly best friends. Shipyards use these machines to remove corrosion from ship components, helping vessels withstand harsh ocean environments. It’s how they keep ships shipshape.

Metal Furniture Production

Even the metal chair you’re sitting on might have met a hanger shot blasting machine. Manufacturers create smooth surfaces for better paint adhesion, resulting in sleek, polished furniture.

Pipeline and Pressure Vessel Manufacturing

Companies making pipes and tanks need spotless surfaces inside and out. Hanger shot blasting reduces the risk of failures, which is crucial when dealing with high-pressure systems.

So there you have it! From cars to ships, these machines play a vital role across various industries. They’re the behind-the-scenes heroes keeping everything running smoothly.

Q2: How the Blasting Media Recovery System Helps?

Ever wondered how a hanger blasting machine keeps chugging along without frequent pit stops? The blasting media recovery system is the secret sauce behind its smooth operation. Let’s dive into how this system lends a hand.

First off, it recycles the abrasive media used in blasting. After the media does its job cleaning your parts, the recovery system scoops it up, filters out dust and debris, and sends it back into the fray. This means less downtime for refills. It’s like having a magic coffee pot that never runs dry—you keep working without missing a beat.

Reusing the media doesn’t just save time; it saves money too. With less need to buy new abrasives, your expenses drop. Over time, these savings stack up. It’s like finding spare change in your couch every day—it may not seem like much at first, but it adds up nicely.

The recovery system also bumps up the quality of the blasting process. By filtering out contaminants, it keeps the media clean, leading to consistent surface finishes on your workpieces. Clean media means better results. It’s the difference between painting with a fresh brush versus one clogged with old paint—the outcome is smoother and more precise.

There’s an environmental perk as well. Recycling the abrasive media means less waste heads to the landfill. You’re not just saving bucks; you’re also doing a solid for Mother Earth. That’s a two-for-one deal anyone can appreciate.

Maintenance gets easier too. Clean media puts less wear and tear on the machine’s components. This leads to fewer breakdowns and a longer lifespan for your equipment. Think of it like regular oil changes for your car—it keeps everything running like a well-oiled machine.

In a nutshell, the blasting media recovery system boosts efficiency, cuts costs, improves quality, helps the environment, and reduces maintenance headaches. It’s the behind-the-scenes hero that keeps the hanger shot blasting machine firing on all cylinders.

Q3: Are Hanger Blasting Machines Eco-Friendly?

Absolutely! Hanger blasting machines are like the green champions of surface preparation.

First off, they recycle abrasive materials. The blasting media gets used again and again, which slashes waste. It’s giving materials a second, third, and even fourth life, keeping them out of the landfill.

They also help keep the air clean. Many of these machines come with dust collection systems that trap particles before they can escape. Imagine a giant vacuum gobbling up all the dust—that’s what’s happening here. This means a cleaner workspace and a happier environment.

No harsh chemicals involved! Traditional methods might rely on nasty solvents, but hanger blasting machines use physical force instead. That means fewer harmful substances sneaking into nature.

Energy efficiency is another big win. Modern hanger blasting machines are designed to use less power without skimping on performance. Lower energy use means a smaller carbon footprint and savings on your energy bill.

By extending the life of your materials, these machines cut down on the need for replacements. Less manufacturing means fewer resources consumed and less pollution. It’s the classic “reduce, reuse, recycle” in action.

In a nutshell, hanger blasting machines are eco-friendly because they recycle materials, improve air quality, avoid harmful chemicals, conserve energy, and prolong product life. Choosing them isn’t just good for your projects—it’s great for the planet too.

Q4: What's the Difference Between Batch and Continuous Shot Blasting Machines?

Ever found yourself scratching your head over the types of shot blasting machines? Let’s break it down in simple terms.

Batch Hanger Shot Blasters

Think of batch machines like baking cookies at home. You mix the dough, bake a tray, and wait for them to finish before starting the next batch. These machines work the same way. You load a group of items, run the cycle, and unload them when they’re done.

Batch machines are great when you need special attention for each group. They’re ideal for handling items of different shapes and sizes. You can adjust settings for each batch, giving you control over the process. The downside? It might take more time if you’re dealing with large quantities.

Continuous Shot Blasting Machines

Now, imagine a conveyor belt at a factory assembly line. Products keep moving along without stopping. That’s how continuous shot blasting machines operate. Items are fed into one end and come out the other, cleaned and ready to go.

These machines are perfect for high-volume production. They keep things moving, boosting efficiency and saving time. If you’re working with a large number of similar items, continuous machines keep the workflow smooth. However, they might not offer the same level of customization as batch machines.

Which One Fits Your Needs?

Choosing between batch and continuous machines depends on what you’re up to. If you need flexibility and handle a variety of items, batch machines are your best bet. They let you fine-tune the process for each group.

On the other hand, if speed and handling large volumes are your priorities, continuous machines are the way to go. They keep the production line rolling without interruptions.

In a Nutshell

Batch machines are like cooking meals to order—personalized and precise. Continuous machines are more like a buffet line—efficient and serving many at once. Pick the one that suits your operation best, and you’ll keep things running smoothly.

Q5: How Often Should I Maintain My Hanger Shot Blast Machine?

Keeping your hanger shot blast machine in good shape is essential for smooth operations. But how often should you give it some TLC? Let’s break it down together.

Daily Checks

Every day, spend a few minutes inspecting your machine. Look for loose bolts, worn parts, or any signs of damage. Listen for unusual noises during operation. It’s like giving your car a quick once-over before hitting the road.

Weekly Maintenance

Once a week, dive a bit deeper. Clean out any dust and debris that might have built up. Check the blast wheels and blades for wear. Replace parts that are showing their age. Think of it as cleaning out your garage on the weekend—it keeps things running smoothly.

Monthly Service

Each month, schedule a more thorough check-up. Lubricate moving parts to reduce friction and prevent wear. Inspect the electrical components for any issues. Make sure filters are clean to maintain proper airflow. Consider it a regular doctor’s visit for your machine.

Quarterly Overhaul

Every three months, it’s wise to perform a comprehensive maintenance session. This might include replacing major components or updating software if needed. It’s like giving your machine a seasonal tune-up to keep it performing at its best.

Annual Inspection

Once a year, have a professional technician conduct a full inspection. They can spot problems you might miss and handle any necessary repairs or upgrades. Think of it as the annual physical that keeps your machine in peak condition.

Why Regular Maintenance Matters

Skipping maintenance can lead to unexpected breakdowns and costly repairs. Regular care extends the life of your machine and keeps it operating efficiently. It’s like changing the oil in your car—you might not see immediate benefits, but it prevents big problems down the road.

Adjust According to Usage

If your machine is running around the clock, you might need to step up the maintenance frequency. Heavy use can wear out parts faster, so staying ahead of issues is crucial.

Final Thoughts

Setting up a maintenance schedule that fits your machine’s workload keeps it running smoothly and saves you time and money in the long run. After all, a well-maintained machine is key to keeping your operations on track.