Tumble Shot Blasting Machine: Revolutionizing Surface Treatment

Updated: November 6, 2025

Unleash the Potential of Precision with Our State-of-the-Art Tumble Type Shot Blasting Machines. Propel your Surface Treatment Capabilities to Unprecedented Heights!

Outline

1. What Is A Tumble Shot Blasting Machine?

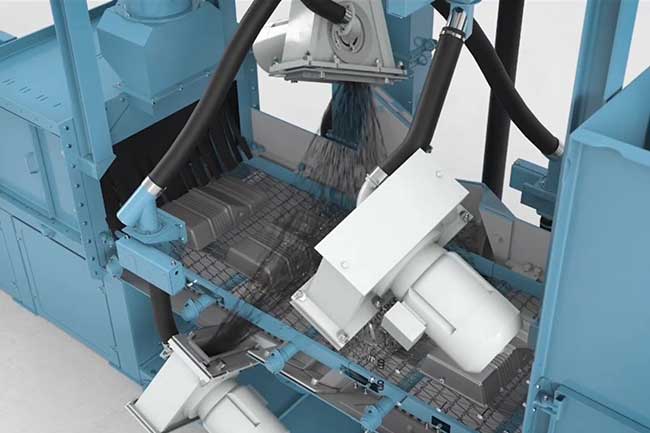

Batch Type Tumblast machines offer a highly efficient and cost-effective solution for surface treatment, particularly for workpieces that are tumble-proof. In this innovative process, parts are processed in batches, undergoing a meticulous stop-start operation to ensure precision and thorough treatment. This method not only enhances cost-effectiveness but also guarantees consistent and reliable results, making it an ideal choice for a wide range of industrial applications.

The controlled and systematic approach of Batch Type Tumblast machines makes them a valuable asset in achieving top-notch surface finishes and meeting specific quality standards. Invest in the power of precision and efficiency with Batch Type Tumblast machines for your surface treatment needs.

2. Hot Products

Safeguarding Success: Ensure Durability and Longevity in Every Blasted Product!

Fed up with constant machine breakdowns?

Invest in reliability with our tumble belt shot blasting machines. From our standard SmartLine blasters to customized non-standard machines, each unit is designed to enhance efficiency while guaranteeing the durability and longevity of your finished products.

Call us today at +86 135 8931 7685

3. Features and Advantages

Batch Type Tumblast machines offer a cost-effective solution for processing parts in a stop-start operation, ensuring efficient cleaning for tumble-proof workpieces. These systems, including tumble blast and drum barrel configurations, incorporate a range of shot blast and workpiece handling technologies.

Key advantages of tumble blast systems include their compact design, established operating principles, high cleaning capacity, gentle tumbling of parts, and thorough exposure of all surfaces to the blasting stream.

These systems are versatile, addressing needs such as desanding castings and descaling forgings or heat-treated workpieces. They come in various designs with steel or rubber conveyors to suit specific requirements.

Barrel-type shot blasting machines, featuring a polygon-shaped trough rocking back and forth, enable intensive and gentle shot blasting at high capacity. The inclusion of automatic loading and unloading ensures an almost continuous process with consistent high performance.

4. Working Video

5. FAQs (Frequently Asked Questions)

Q1: How Do Tumble Blasting Machines Work?

Tumble shot blasting machines operate in batch mode, meaning they process a group of workpieces together. These machines can be integrated into existing production plants for continuous workflow by using appropriate loading and unloading devices.

The operation begins with the loading device transferring the workpieces into the trough-shaped shot blast chamber. This chamber typically contains a continuous rubber conveyor belt or a steel apron conveyor with adjustable lateral disks. As the workpieces move through the chamber, shot, burrs, flashes, scale, and sand deposits are removed by the lower vibrating deck. On smaller machines, there is an optional separator located after the vibrating deck to further refine the process.

The speed of the conveyor belt can be adjusted to control the tumbling behavior of the workpieces, allowing for individual dwell times during the blasting sequence. After the blasting process is complete, the belt can run in reverse to unload the workpieces from the machine. Depending on production requirements, loading and unloading can be done manually, mechanically, or automatically, facilitating integration into continuous production sequences.

This versatile approach makes BlastKing’s tumble blasting machines suitable for various applications, offering flexibility and efficiency in surface preparation and treatment processes.

Q2: What are the tumble shot blasting machines used for?

Tumble shot blasting machines are versatile tools used for various surface treatment applications, including:

- Cleaning: Removing rust, scale, paint, and other contaminants from pumps, fittings, stampings, and laser-cut components.

- Coring: Preparing surfaces of fittings, steel castings, and engine components by removing core sand or other residues.

- Precision shot blasting: Cleaning and preparing precision (investment) castings and non-ferrous forgings for subsequent processes.

- Smoothing: Smoothing out etched, corroded, or rough surfaces, as well as removing processing marks to achieve a uniform finish.

- Decorative shot blasting: Enhancing the appearance of light alloy, stainless steel, and non-ferrous metal surfaces for decorative or aesthetic purposes.

- Hardening: Strengthening high-stress parts, such as springs, rings, and gearbox components, by imparting compressive stresses through shot peening.

- Deburring: Removing burrs and sharp edges from small parts, stamped and milled components, and sintered metal parts to improve their quality and safety.

These machines offer efficient and effective surface preparation solutions across a wide range of industries, contributing to improved product quality and performance.

Q3: What are the steel belt tumble shot blasting machines used for?

Steel belt tumble shot blasting machines are utilized for various surface treatment processes, including:

- Deburring: Removing burrs and sharp edges from mass-produced parts to improve their quality and functionality.

- Descaling: Eliminating scale and oxide layers formed during manufacturing processes, ensuring smooth and clean surfaces.

- Sand removal: Clearing sand and other abrasive residues from workpieces, preventing contamination and improving surface quality.

- Derusting: Removing rust and corrosion from metal parts, restoring their appearance and integrity.

These machines can operate independently or as part of a production line, offering flexibility in application. BlastKing offers steel belt tumble shot blasting machines in different sizes and configurations to suit specific needs. Equipped with reliable BlastKing high-performance turbines and maintenance-friendly cartridge filter systems, these machines ensure efficient and effective surface treatment for various industries.

Q4: How do I choose between a wear-resistant rubber belt and a steel belt for the tumble-shot blasting machines?

When choosing between a wear-resistant rubber belt and a steel belt for tumble shot blasting machines, consider the following factors:

-

Material Compatibility: Assess the type of workpieces you’ll be processing and their compatibility with each belt material. Some materials may be better suited for contact with rubber belts, while others may require the durability of a steel belt.

-

Surface Finish Requirements: Determine the desired surface finish of the workpieces after shot blasting. Steel belts may produce a slightly different surface finish compared to rubber belts, so consider which option aligns better with your quality standards.

-

Wear Resistance: Evaluate the level of wear and tear expected during operation. Steel belts are highly durable and resistant to abrasion, making them suitable for heavy-duty applications with abrasive materials. Rubber belts offer good wear resistance and flexibility but may not be as durable as steel belts in certain conditions.

-

Noise and Vibration: Consider the noise and vibration levels associated with each belt type. Rubber belts tend to absorb more noise and vibration, contributing to a quieter and smoother operation compared to steel belts, which may produce more noise and vibration.

-

Maintenance Requirements: Assess the maintenance needs of each belt type. Rubber belts may require more frequent inspections and replacements due to wear and tear, while steel belts generally offer longer service life with minimal maintenance.

-

Cost Considerations: Compare the initial cost and long-term maintenance expenses associated with each belt type. While steel belts may have a higher initial cost, they often offer better durability and lower long-term maintenance costs compared to rubber belts.

Ultimately, the choice between a wear-resistant rubber belt and a steel belt depends on your specific application requirements, budget constraints, and preferences for surface finish and operational characteristics.

-

Q5: How does BlastKing optimise the shot blasting effect with a tumble shot blasting machine?

During shot blasting, the workpieces, irrespective of their size and shape, undergo even and continuous tumbling. This is essential for ensuring effective and uniform treatment of all surfaces. As the workpieces tumble, shot removal occurs continuously, allowing for thorough cleaning of workpiece interiors and cavities. To ensure all shot is completely removed, the final tumbling time following the shot blast sequence can be adjusted to accommodate the specific type of workpieces being cleaned. Additionally, the tightly sealed and leak-proof blast chamber helps minimize shot consumption.

Q6: Can BlastKing's tumble belt shot blasters be integrated into automatic production line?

BlastKing tumblast machines are engineered for batch operations, offering versatility in integrating them into existing production plants to ensure a continuous workflow. A loading device transports workpieces to the trough-shaped shot blast chamber, equipped with a continuous rubber conveyor belt or a steel apron conveyor and adjustable lateral disks. Shot, burrs, flashes, scale, and sand deposits are efficiently removed by the lower vibrating deck before reaching the optional separator in smaller machines.

Belt speeds can be adjusted to match the tumbling behavior of the workpieces, facilitating individual dwell times during the blasting process. Upon completion, the workpieces are unloaded from the machine by running the belt in reverse, allowing them to be placed in containers or onto conveyor belts. Loading and unloading procedures can be tailored to production requirements, whether manual, mechanical, or automatic, enabling seamless integration of BlastKing’s tumble blaster machines into continuous production sequences.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685