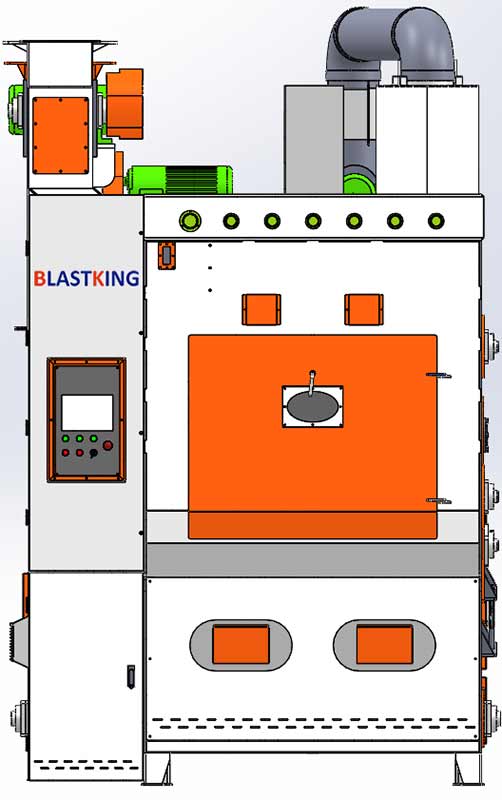

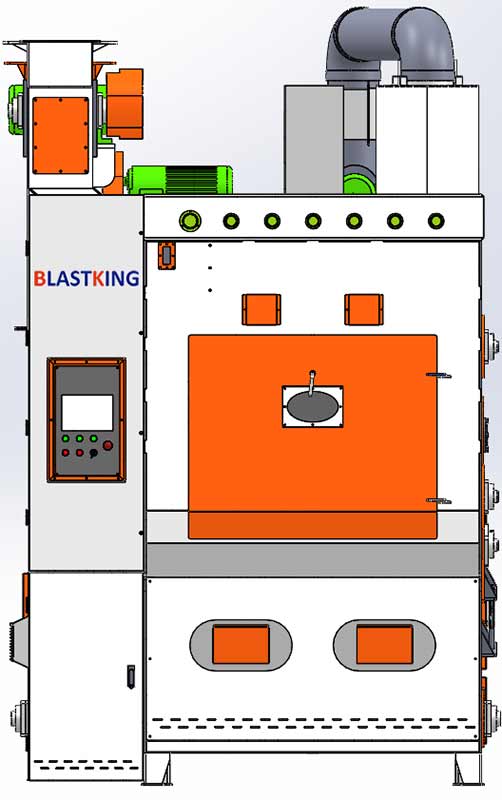

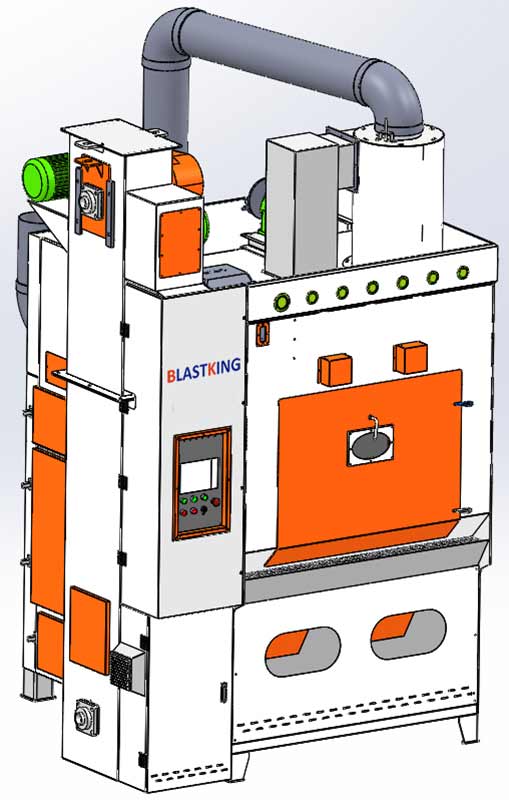

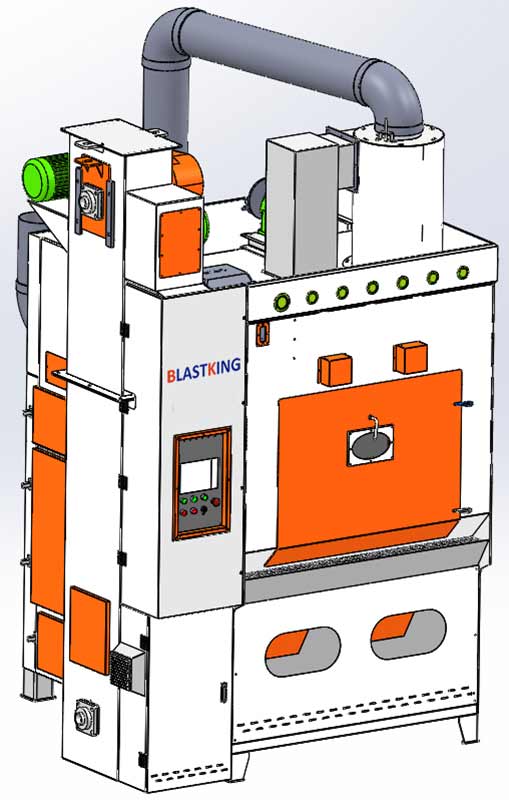

Tumble Sand Blasting Machine — Where Power Meets Precision

Updated: November 6, 2025

Discover how BlastKing’s tumble sand blasting machines deliver flawless finishes, faster production, and unmatched precision for every industry. Power meets perfection here.

Outline

1. Tired of Wasting Hours Cleaning Parts Manually?

If your team still spends hours hand-cleaning metal parts, it’s time for a reality check. Grinding wheels, wire brushes, and outdated blasters cost you money, labor, and consistency.

BlastKing’s tumble sand blasting machine series changes the game — combining power, precision, and automation to deliver uniform, high-quality surface cleaning across thousands of components at once.

Whether you call it a tumble blaster, tumble belt sand blasting machine, or rubber belt tumble sand blaster, BlastKing builds each model to clean faster, safer, and smarter — so you can spend less time fixing surfaces and more time shipping finished products.

“Load it, run it, forget it.” That’s the BlastKing promise — every tumble sand blast machine works as hard as your production line does.

2. How BlastKing’s Tumble Sand Blasting Machine Works

The BlastKing tumble sand blasting machine is engineered for continuous, automatic cleaning of castings, bolts, forgings, and small metal parts.

It’s more than a machine — it’s a self-contained blasting ecosystem. Load your parts, close the door, press start. The rest happens on its own.

How A Tumble Sand Blaster Works

-

Abrasive Acceleration: Compressed air drives abrasive media through boron carbide nozzles, propelling it with controlled pressure.

-

Tumble Action: Parts rotate inside a durable rubber or steel belt drum, tumbling naturally for full 360° coverage.

-

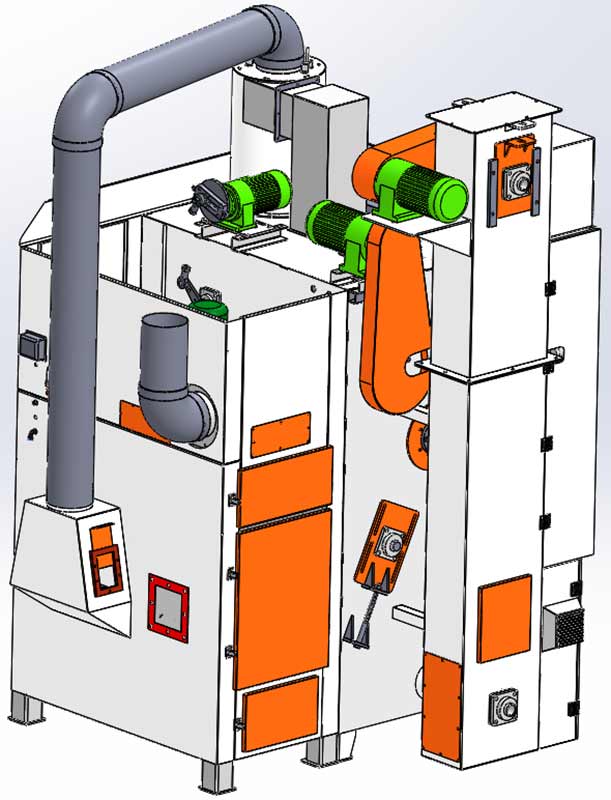

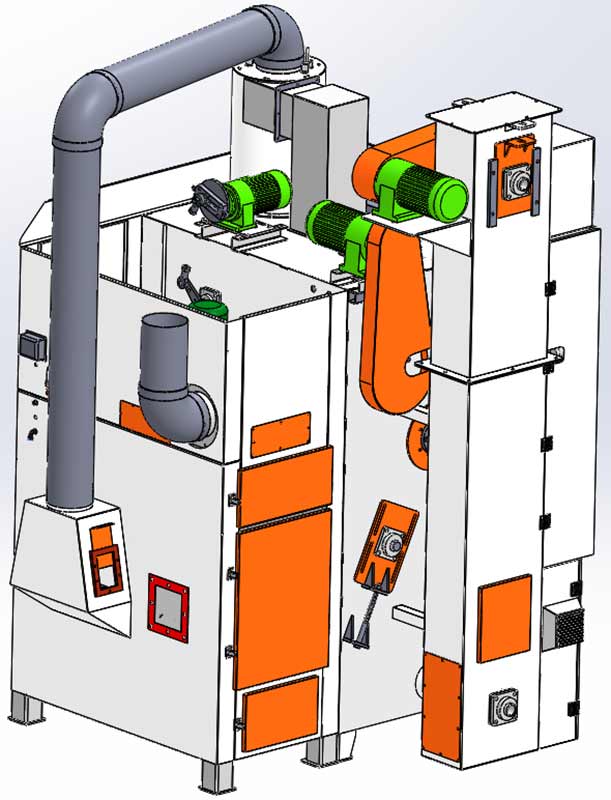

Abrasive Recovery: A screw conveyor and bucket elevator collect, separate, and recycle blasting media automatically.

-

Dust Extraction: A pulse-jet cartridge dust collector and cyclone separator maintain clear air and stable negative pressure.

-

Smart Control: A PLC + touchscreen interface automates every step — from blast pressure to rotation speed — ensuring repeatable quality.

Each tumble belt sand blast machine shares the same BlastKing DNA — robust steel construction, efficient abrasive recovery, and guaranteed uniform cleaning.

Still Cleaning Parts the Hard Way?

Stop Wasting Time, Money, and Labor on Outdated Surface Cleaning Methods.

Your production line deserves better than manual scrubbing, grinding, or low-efficiency blasting. Each hour spent fighting rust and scale is an hour lost from profit. BlastKing’s Tumble Sand Blasting Machines automate the pain away — giving you faster, cleaner, and more consistent finishes across thousands of metal parts.

Call us today at +86 135 8931 7685

5. Built for Results, Backed by BlastKing’s 40+ Years of Experience

Since 1982, BlastKing has been designing surface preparation machines trusted by clients in over 56 countries. Every tumble belt blaster is engineered, assembled, and tested in-house — ensuring reliability that outlasts ordinary machines.

Key Technical Highlights

-

Cabinet Construction: Heavy-duty 3–5 mm steel plates, fully welded and lined with wear-resistant rubber.

-

Dust Collection: Pulse-jet cartridge collector with 5.5–7.5 kW fan motor, designed for continuous use.

-

Blast Guns: High-performance boron carbide nozzles (Ø8 mm) for uniform flow and long service life.

-

Automation: XINJE PLC control system with touchscreen interface and data monitoring.

-

Drive Mechanism: Servo-controlled rotation, planetary reducer, and smooth, synchronized tumbling.

-

Air System: Adjustable 1–7 bar blasting pressure, compatible with steel shot, grit, glass beads, and ceramics.

Every BlastKing tumble sand blaster is a blend of engineering rigor and user-centered design — giving you top performance, low noise, and lasting value.

4. Inside the Engineering — The BlastKing Advantage

1. Chamber Strength That Lasts

Each tumble belt sand blast machine features a fully welded steel chamber reinforced against vibration. Internal rubber liners absorb impact and reduce wear — meaning less maintenance and quieter operation.

2. Precision Blast Guns

The BlastKing B4 blast gun system delivers consistent flow, low turbulence, and stable media velocity. Made with boron carbide nozzles, it provides over 600 hours of effective blasting before needing replacement.

3. Automated Abrasive Recovery

A bucket elevator and screw conveyor system recycle abrasives efficiently, separating usable media from dust. No waste. No mess.

4. Smart Control Panel

Operators manage the full cycle with an intuitive HMI touchscreen. Set blast time, rotation speed, or cycle sequence — the PLC system handles it automatically.

5. Safety & Reliability

Every BlastKing tumble sand blasting machine includes:

-

Emergency stop systems

-

Door interlocks

-

Anti-static protection

-

Automatic fault alarms

-

Real-time status display

No shortcuts. No compromises.

6. Cleaner Air, Cleaner Results

The BlastKing tumble airblast machine uses a dual-filtration dust collector to ensure both operator safety and environmental compliance.

By maintaining negative pressure in the chamber, it eliminates dust leakage and ensures a spotless workspace. Pulse-jet cleaning keeps filters clear — maintaining airflow, energy efficiency, and long-term reliability.

Result: Cleaner air, cleaner surfaces, cleaner profits.

Trusted Worldwide Since 1982

From Foundries to Aerospace, BlastKing Tumble Blasters Lead the Way.

With over 5,000 installations across 56 countries, BlastKing’s tumble sand blasting machines are trusted by manufacturers who can’t afford downtime. Each tumble airblast machine delivers high-speed, uniform cleaning for castings, bolts, and forgings — achieving finishes that make coatings last longer and products look better.

Call us today at +86 135 8931 7685

5. Built for Every Industry

BlastKing tumble sand blasting machines are trusted across industries where surface perfection is non-negotiable:

-

Foundries & Forging: Cleaning rust, sand, and scale from cast iron.

-

Automotive & Aerospace: Pre-coating preparation for aluminum and steel parts.

-

Hardware & Fasteners: Achieving uniform texture on bulk metal components.

-

Machinery & Construction: Removing weld slag, burrs, and corrosion.

-

Precision Manufacturing: Finishing delicate aluminum and alloy parts.

Whether you choose a tumble sand blasting machine or a tumble shot blasting machine, every model is built to increase throughput, consistency, and finish quality.

6. Why Global Manufacturers Choose BlastKing

1. Proven Reliability

More than 5,000 BlastKing wheelblast & airblast technology machines installed worldwide since 1982 — many clients now on their second or third unit.

2. Lower Costs

Up to 40% reduction in abrasive usage through closed-loop recovery and intelligent airflow design.

3. Minimal Maintenance

Easy-to-replace liners, quick-access service panels, and modular design keep downtime near zero.

4. Energy Efficiency

Optimized air systems and high-efficiency motors save energy without sacrificing blast force.

5. Long Service Life

Every component — from the rubber belt to the blast guns — is selected for longevity, cutting replacement costs dramatically.

Engineered for Power, Built for Precision

The Details That Define BlastKing’s Quality.

Every BlastKing tumble sand blasting machine is a result of smart engineering:

-

Heavy-duty welded cabinet (3–5 mm steel plate) with rubber liners.

-

Dust-free pulse jet collectors maintaining clean air and visibility.

-

Servo-driven rotary motors for smooth, controlled tumbling.

-

Energy-efficient design lowering operating costs by up to 25%.

Call us today at +86 135 8931 7685

7. Safety, Sustainability, and Service

At BlastKing, we believe a powerful machine should also be a safe one.

Our tumble belt sand blast machines feature:

-

Sealed chambers with negative-pressure design

-

Pulse-clean dust collectors

-

Low-noise fans

-

CE and ISO 9001 compliance

Service Commitment

-

1-year warranty (excluding wear parts)

-

24-hour response time

-

On-site support within 7 working days

-

Lifetime maintenance support at cost price

Your success is our service guarantee.

8. Your Competitors Are Already Upgrading — Why Aren’t You?

You’ve seen the numbers. You’ve seen the results.

Manual cleaning is history — BlastKing tumble sand blasting machines are the future.

From compact tumble sand blasters to custom industrial-grade pass through sand blasting machine systems, BlastKing’s lineup delivers power, precision, and profit.

Your surfaces deserve better. So does your business.

Join the Global Movement Toward Smarter, Cleaner, Faster Production.

Manual cleaning is history. Automation is the future.

BlastKing’s tumble belt sand blasting machines are redefining surface preparation — making every finish flawless, every cycle efficient, and every investment worthwhile.

Whether you need a compact tumble belt blaster or a multi-station tumble airblast system, we’ll tailor it to your exact process.

Call us today at +86 135 8931 7685

9. FAQs (Frequently Asked Questions)

1. What is a tumble sand blasting machine?

A tumble sand blasting machine is an automated surface-cleaning system that uses rotating belts or drums to tumble parts while blasting them with abrasive media. This ensures consistent, 360-degree cleaning for castings, bolts, and small components.

2. What materials can be cleaned with a BlastKing tumble blaster?

BlastKing tumble blasters can process steel, iron, aluminum, brass, and non-ferrous metals. They effectively remove rust, scale, paint, and burrs while improving coating adhesion.

3. How does the BlastKing tumble belt sand blasting machine work?

The machine combines air pressure and abrasive flow through boron-carbide nozzles while rotating the parts on a rubber or steel belt. The result is fast, uniform surface preparation with minimal operator involvement.

4. What are the benefits of using a rubber belt tumble sand blaster?

A rubber belt tumble sand blaster offers gentle part handling, reduced noise, full abrasive recovery, and superior energy efficiency. It’s ideal for delicate or precision components requiring smooth, uniform finishes.

5. Why choose BlastKing tumble sand blasting machines over traditional methods?

BlastKing machines reduce labor time, cut abrasive waste, improve surface quality, and ensure consistent results. They provide automated cleaning that’s faster, safer, and more cost-effective than manual blasting or acid pickling.

6. What maintenance is required for a BlastKing tumble sand blaster?

Regular inspection of blast nozzles, rubber liners, and dust filters is recommended. The abrasive recycling and dust collection systems should be cleaned periodically to maintain maximum efficiency and consistent blasting performance.