Structural Steel Shot Blasting Machine: Your Ultimate Solution for Clean, Rust-Free Steel

Updated: November 7, 2025

Discover how a structural steel shot blasting machine can revolutionize your production process in 2024, enhancing efficiency, quality, and cost-effectiveness.

Outline

1. What Is The Structural Steel Shot Blasting Machine?

Introduction

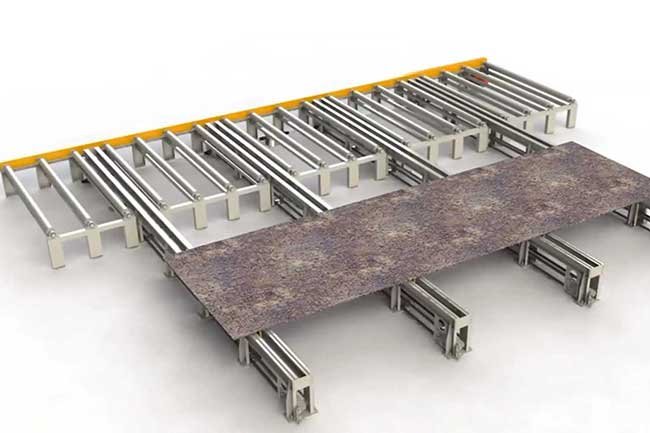

The structural steel shot blasting machine is a cornerstone of modern steel fabrication processes, providing essential cleaning and surface preparation for steel components. This machinery ensures the removal of rust, scale, and other surface contaminants, enhancing the durability and aesthetic quality of steel structures. The integration of shot blasting machines into manufacturing lines facilitates high efficiency and optimal performance in various industrial applications.

Machine Overview

The construction steel shot blasting machine is engineered to handle various steel profiles, including beams, pipes, and plates. It operates by propelling abrasive materials, typically steel shots or grits, at high velocities against the steel surfaces. This process not only cleans the surface but also imparts a uniform texture, improving the adhesion of subsequent coatings.

Transform Your Steel: The Ultimate Structural Steel Shot Blasting Solution

Are your steel surfaces failing to meet quality standards?

Ever feel like you’re chasing your tail trying to get that perfect steel finish? Our shot blasting machine is here to save the day, turning your steel from drab to fab in no time. Imagine every piece coming out sparkling clean and ready to shine!

Call us today at +86 135 8931 7685

2. Features

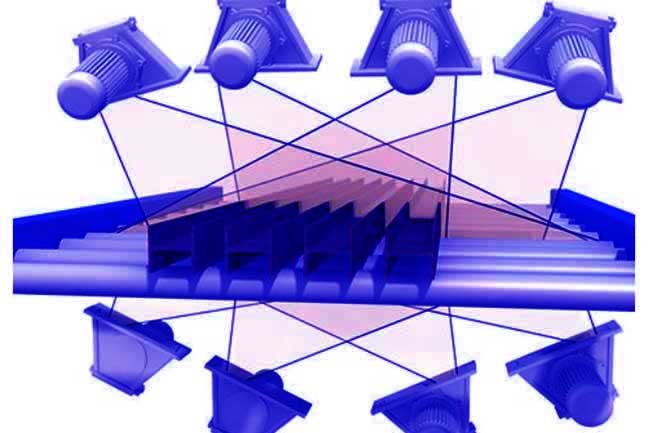

High-Performance Turbines: The machine is equipped with high-efficiency turbines that ensure optimal abrasive acceleration, resulting in superior cleaning performance. These turbines are designed for longevity and minimal maintenance.

Adjustable Blast Settings: Operators can fine-tune the blast intensity and pattern to match specific job requirements. This flexibility is essential for handling different steel grades and contamination levels.

Sturdy Construction: Built with high-quality materials, the machine can withstand the rigors of continuous operation in industrial environments. The solid construction guarantees reliable performance and a long service life.

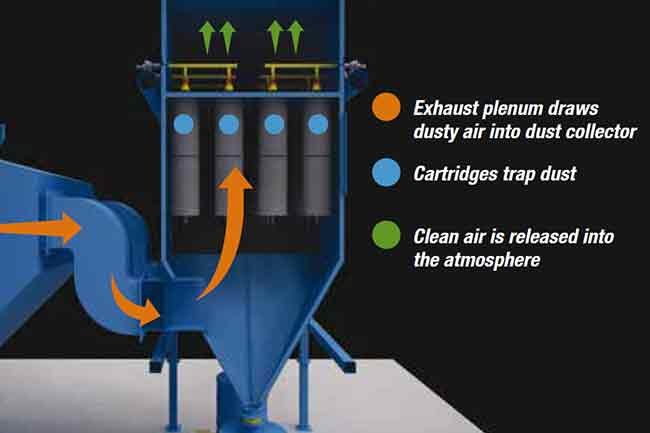

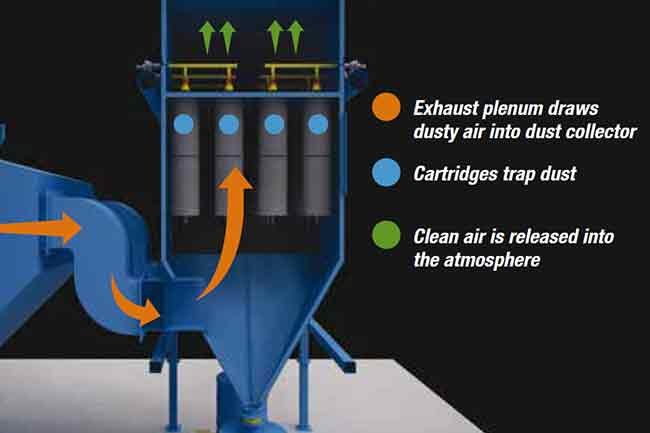

Advanced Filtration System: An integral part of the machine is its dust and debris filtration system. This system maintains a clean working environment by efficiently collecting and containing airborne particles generated during the blasting process.

Automated Operation: Modern structural steel shot blasting machines come with automated controls that enhance operational efficiency and reduce the need for manual intervention. These controls are often integrated with user-friendly interfaces for ease of use.

3. Applications

Structural steel shot blasting machines are used in a variety of applications, including:

Construction: Preparing steel beams and columns for assembly in buildings and infrastructure projects.

Shipbuilding: Cleaning and preparing ship hulls and components to prevent corrosion and enhance paint adhesion.

Automotive Industry: Treating steel parts for vehicles to ensure they meet stringent quality and durability standards.

Energy Sector: Maintaining and refurbishing steel structures used in power plants and refineries.

Maximize Efficiency, Minimize Downtime

Losing precious time on manual surface preparation?

Time is money, right? Stop wasting it on tedious manual prep. Our machine takes the grunt work out of the equation, letting your team focus on crafting those stellar steel structures without missing a beat.

Call us today at +86 135 8931 7685

4. Operational Benefits

Improved Surface Quality

Shot blasting machines deliver superior surface preparation, removing rust, mill scale, and other contaminants. This results in a clean surface that enhances paint adhesion and overall durability of steel components.

High Throughput and Automation

Modern shot blasting machines support high throughput rates, with some models capable of processing up to 6 meters of steel per minute. The high degree of automation reduces labor costs and increases operational efficiency, making them ideal for large-scale manufacturing environments.

Integration into Manufacturing Lines

Shot blasting machines are designed for easy integration into existing manufacturing lines. Their modular construction allows customization to meet specific operational requirements, ensuring seamless incorporation into production workflows.

Precision Cleaning for Perfect Results

Frustrated with inconsistent cleaning results?

Ever feel like you’re playing roulette with your cleaning results? Say goodbye to that gamble. Our machine ensures a flawless, uniform clean every single time, making your steel look like it just stepped out of a spa day.

Call us today at +86 135 8931 7685

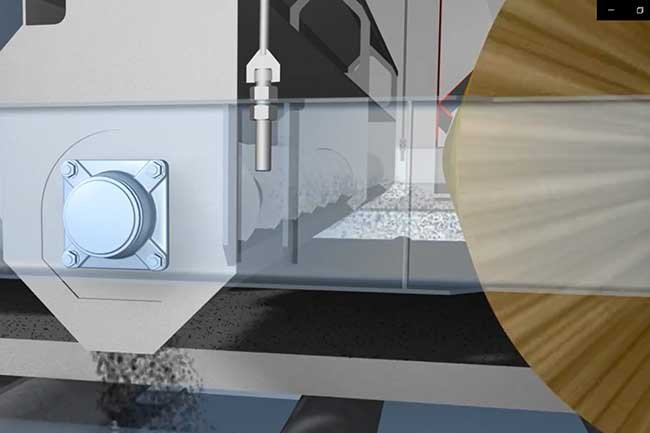

5. Cartridge Filter Unit: Keeping Things Clean

Ever dealt with the mess left behind after blasting? Our cartridge filter unit has got you covered. It separates rust, scale, and broken-down media dust, ensuring your workspace stays clean.

Highlights:

- Impact Separator: This clever device keeps the filter cartridge from wearing out too quickly and acts as a spark extinguisher.

- Automatic Cleaning: The filters are cleaned automatically with air pressure pulses, adjustable based on the dust type and amount.

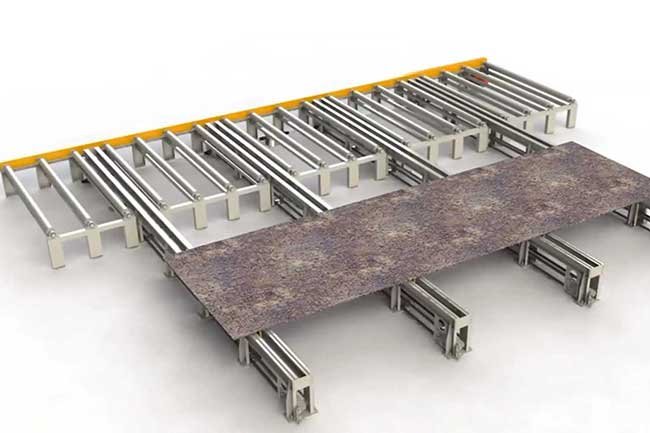

6. Loading and Unloading: Smooth and Efficient

We know time is money, so our machine is designed to keep things moving swiftly. Standard roller conveyor inlets and outlets are powered by the machine’s central drive, but for extra efficiency, you can add a separate drive unit synchronized with the frequency converter.

Boost Your Efficiency:

- Handling Bowed Workpieces: For workpieces that need extra care, a longer collection track with a reclamation conveyor ensures every bit of blast media is returned to the machine.

- Cross-Feeding System: Integrate it into a sawmill/bore production line, and watch your efficiency soar.

7. Abrasive Blast Media: The Right Mix for the Right Job

Choosing the right blast media is like choosing the right tool for the job. For most roller conveyor setups, round blast media (cast steel shot or cut wire steel shot) is ideal. The media circulates within the machine, continuously cleaned of contaminants.

Here’s the Scoop:

Coarse Workpieces: Use a coarse abrasive media mix (steel ball shot size S390 and above).

Delicate Workpieces: Go for a fine abrasive media mix (steel ball shot size S330 and below).

8. Shot Blast Cabinet: Built to Last

Our shot blast cabinets are made entirely of manganese, known for its excellent blasting properties. This ensures durability and effectiveness, no matter how tough the job.

Durable Design:

High-Wear Areas: Extra 10mm to 16mm thick manganese plates in the hot spot areas, easily replaceable.

Leak Prevention: Rubber layers in high-wear areas prevent shot leakage, mounted in a V-Track for easy replacement.

9. Abrasive Removal Unit: Clean and Ready to Go

After blasting, your workpieces might still have some blast media clinging on. Our abrasive removal unit takes care of that with a rotating brush and a blow-off station using high-pressure ventilators.

Keep It Clean:

- Rotating Brush: Interchangeable brush segments ensure thorough cleaning.

- Adjustable Framework: Keeps the brush and screw conveyor positioned correctly for different-sized workpieces.

Cost-Effective Surface Preparation

Spending too much on maintenance and surface prep?

Who doesn’t love saving a buck? Our shot blasting machine is not only a time-saver but a money-saver too. It trims down labor costs and reduces material waste, giving your budget a much-needed breather.

Call us today at +86 135 8931 7685

10. Choosing the Right Shot Blasting Machine

Factors to Consider

When selecting a shot blasting machine, it is essential to consider the following factors:

- Capacity: Ensure the machine can handle the size and volume of steel components.

- Automation Level: Higher automation levels reduce labor costs and increase efficiency.

- Durability: Choose machines constructed from high-quality materials to ensure longevity.

- Safety Features: Ensure the machine includes essential safety features such as emergency stop buttons and protective enclosures.

Cost Analysis

Investing in a shot blasting machine involves analyzing both initial and ongoing costs. While the initial investment may be significant, the long-term benefits of improved efficiency, reduced labor costs, and enhanced product quality can result in substantial savings.

11. Future Trends in Shot Blasting Technology

Increased Automation

The future of shot blasting technology is geared towards increased automation, further reducing labor costs and enhancing operational efficiency. Automated control systems are expected to become more sophisticated, offering greater precision and consistency.

Advanced Materials

Developments in abrasive materials will continue to improve the effectiveness and environmental impact of shot blasting processes. Innovations in recyclable and less hazardous abrasives are anticipated to drive industry advancements.

Integration with Digital Technologies

The integration of shot blasting machines with digital technologies, such as real-time monitoring and predictive maintenance, is set to revolutionize the industry. These advancements will enable more efficient operation, reduced downtime, and optimized resource utilization.

12. BlastKing Walkthrough

13. Conclusion

The structural steel shot blasting machine is essential for anyone in the steel fabrication industry. It’s efficient, reliable, and ensures your steel is in prime condition for subsequent processes. This machine can be a Tunnel Type Shot Blasting Machine, Roller Conveyor Shot Blasting Machine, or Blast Room, among others. By understanding its features, applications, and maintenance requirements, you can maximize the benefits of this powerful tool and maintain smooth operations.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685