Spinner Hanger Shot Blasting Machine

Updated: November 7, 2025

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

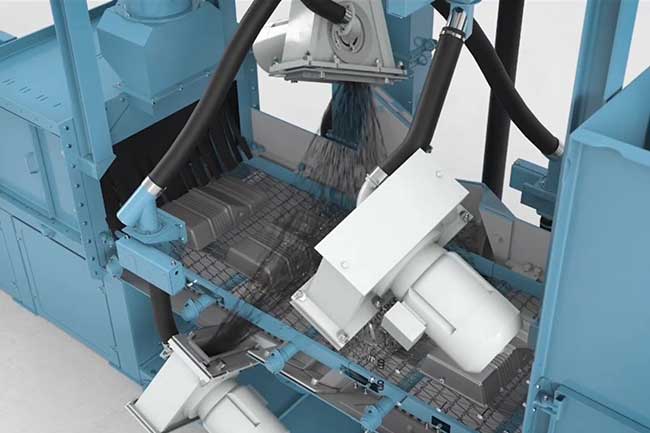

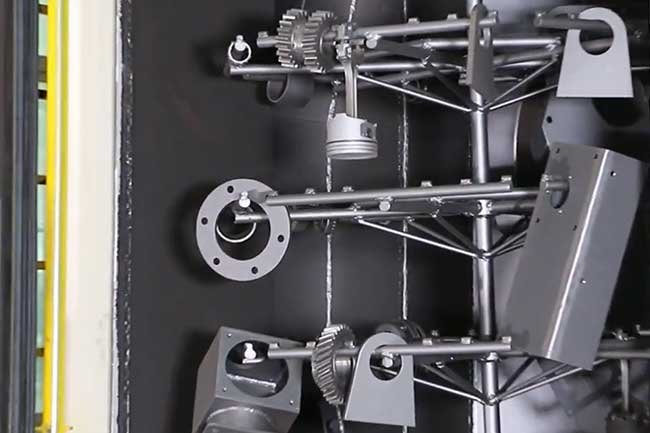

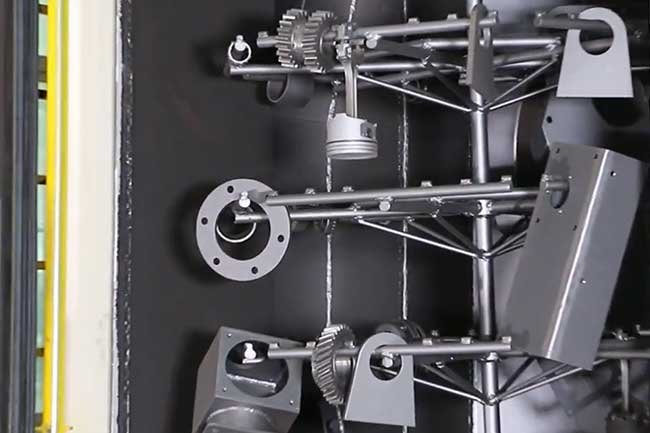

BlastKing HB Hanger type blasting machines are versatile and reliable and provide practical and economical blast cleaning of various component sizes and complexities.

They are ideal for foundry and forge applications, including cast, forge, hardened or heat-treated parts. The HB hanger shot blasters stand for long-lasting manufacturing quality and provide operational reliability for many years, even in demanding service conditions.

1. Features

- Versatile transport technology

- Highly efficient blast wheels

- Multiple machine sizes and variations are available

- Economical abrasive consumption, reliable cleaning and dust collection

- Easy integration into existing production lines

- High sand separation capacity with combined magnetic and air-wash separation

- Low maintenance, and maintenance-friendly design (easy access to maintenance areas, external bearings, easily replaceable wear parts)

2. Applications

- Desanding, decoring, and surface finishing of iron, steel, and light metal castings, including parts susceptible to breakage and impact damage

- Descaling of forgings, hardened or heat-treated steel parts

Surface preparation before coating or other applications - Deburring and homogenizing diecast parts

- Peening dynamically stressed components

- Removal of mill and forge scale as well as rust

roughness - Shot peening to increase fatigue strength

- Corrosion, rust, and heat scale removal

3. Key Benefits

4. High Performance Spinner Hanger Shot Blaster

The workpieces are transported manually on rotating hooks or automatically on an overhead rail system into the blast cabinet. The blast cycle runs in accordance with the preset program and blast time. The main components features are as follows:

- Sturdy, welded housing structure in manganese steel reinforced with profiles

- Additional bolted and suspended manganese wear plates in the hot area

- Heavy-duty, direct drive blast wheels

- Overhead monorail in a variety of configurations

5. Working Video

6. Basic Specification

| Machine Type | HB7/12 | HB10/16 | HB12/18 | HB14/22 | HB16/23 | HB18/25 | HB30/30 | |

|---|---|---|---|---|---|---|---|---|

| Max. diameter per cluster(mm) | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 3000 | |

| max. height per cluster(mm) | 1200 | 1600 | 2000 | 2200 | 2300 | 2500 | 3000 | |

| Max. weight per cluster(kg) | 600 | 800 | 1000 | 2000 | 3000 | 5000 | 10000 | |

| No. of wheelsx Power(kw) | 2x 7.5 | 2x 7.5/11 | 2x11/15 | 3x 7.5/11/15 | 3x 7.5/11/15 | 4x 7.5/11/15 | 5x7.5/11/15 | |

| Foundation pit | no | no | no | no | yes | yes | yes |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685