Smartline Tumble Shot Blaster

Updated: August 14, 2025

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

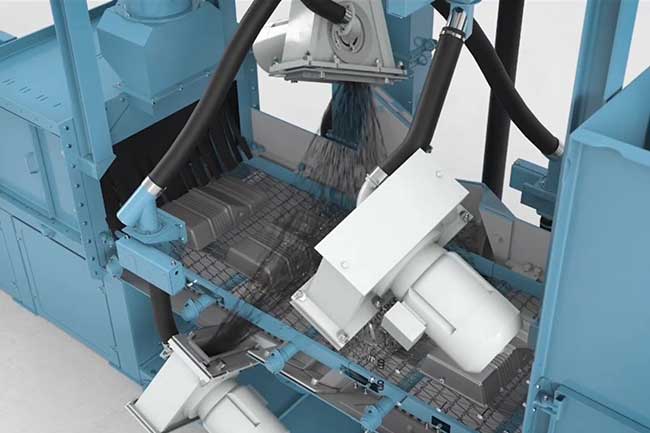

The SmartLine tumble shot blast machines are ideal for cleaning and finishing batches of components such as castings and small fabrications.

The workpieces, regardless of size and shape, are evenly and continuously tumbled during shot blasting. This process is necessary for the effective and uniform treatment of all surfaces. During tumbling, the workpieces continually undergo shot removal, enabling workpiece interiors and cavities to be perfectly cleaned. For the complete removal of all shots, the final tumbling time that follows the shot blast sequence can be regulated to suit the type of workpieces being blast cleaned. The tightly sealed, leak-proof blast chamber minimizes shot consumption.

1. Features

- Extremely compact design, minimum floor space required

- Totally self-contained, includes a dust collector, separator, cartridge filtration system

- “Plug and play“ characteristics, i.e. the machines can be installed and put into operation in the shortest possible time

- No special foundations are required, and no extra ducting needed

- All machines feature the ORICA high-efficiency blast wheel

- Full safety interlocks

- Low noise levels

2. Applications

For the treatment of, steel fabrication, PEB beams, plates, and profiles in the steel manufacturing and processing industry.

- Cleaning

- Corrosion removal

- Paint stripping

- Rust and heat scale removal

3. Key Benefits

4. Highest Performance Tumble Shot Blaster

The tumble shot blast machines are ideal for cleaning and finishing batches of components such as castings and small fabrications. All models are self-contained and include automatic sweep up, collection, separation of abrasive, and dust collection. No special foundations or additional ducting are required. Most models can achieve further efficiency by adding automatic loading and unloading equipment.

All MB100G to MB400G series machines are equipped with wear-resistant rubber belts. These machines are also suitable for processing light alloy parts.

5. Working Video

6. Basic Specification

| Type | MB150 | MB300 | MB400 |

|---|---|---|---|

| Productivity(t/h) | 0.6-1.2 | 1.5-2.5 | 3-5 |

| Max volume charge (dm3) | 150 | 300 | 400 |

| Max advised load (kg) | 200 | 600 | 800 |

| Drum diameter (mm) | 650 | 1000 | 1000 |

| Number of blast wheels | 1 | 1(2) | 1(2) |

| Wheel power (kW) | 7.5 (11) | 11/15 (2x11) | 11/15 (2x11) |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685