Skew roll Shot Blaster for Cylindrical Parts

Updated: August 15, 2025

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

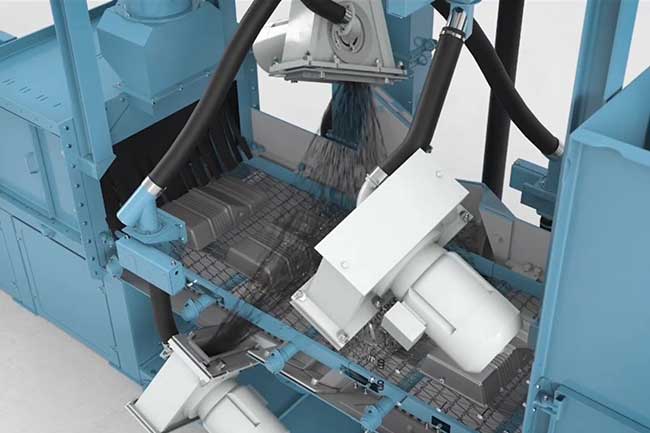

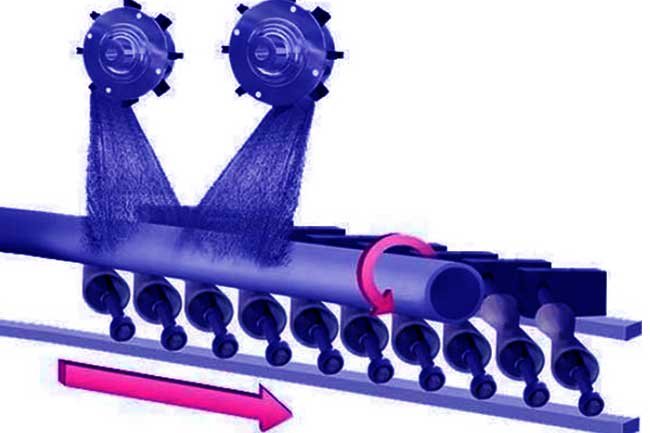

BlastKing Skew roll shot blasting machines are mainly for the automatic shot blast of the outside surface of pipes, tubes, bars, gas bottles, and other cylindrical bodies.

Different types of shot blasting machines with Diabolo rollers are available, having a variable number of blast wheels, varying sizes of diabolo rollers, and installed powers, depending on the customer’s production requirements.

BlastKing skew-roll shot blast machines include an air wash and dust collection system to remove contaminants and fines, control dust, and maintain correct abrasive size.

1. Features

- Proven high-performance ORICA® double-disc blast wheels

- Various numbers of wheels are possible

- Integrated filter unit possible – depends on machine size

- abrasive removal device

- Automatic PLC control

- Workpiece recognition

2. Applications

For the treatment of cylindrical parts such as cylinders, bars, pipes, etc.

- Cleaning

- Corrosion removal

- Paint stripping

- Rust and heat scale removal

3. Key Benefits

4. Highest Performance Skew Roll Shot Blaster

The BlastKing skew-roll shot blasting machine is a fully automated system designed to remove rust and scale from many cylindrical parts:

- Pipes

- Tubes

- Round bars

- Torsion bars

- Drill rods

- Re-bars

- Gas cylinders, etc.

The workpieces pass through the blast machine on a specially designed skew roll-type material handling system. Extensive high-production blast cabinets can handle various work sizes at variable cleaning speeds.

5. Working Video

6. Basic Specification

| Type | SR 8-20 | SR24-60 | SR60-150 |

|---|---|---|---|

| Maxi. Pipes diameter (mm) | 200 | 600 | 600-1500 |

| Work speed (m/min) | 0.5-18 | 0.5-18 | 0.5-18 |

| Number of blast wheels | 2/4/6 | 2/4/6 | 2/4/6/8 |

| Power per blast wheel (kW) | 7.5/11/15/18.5 | 7.5/11/15/18.5 | 7.5/11/15/18.5/22 |

| Roller pitch (mm) | 600 | 600 | 600 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685