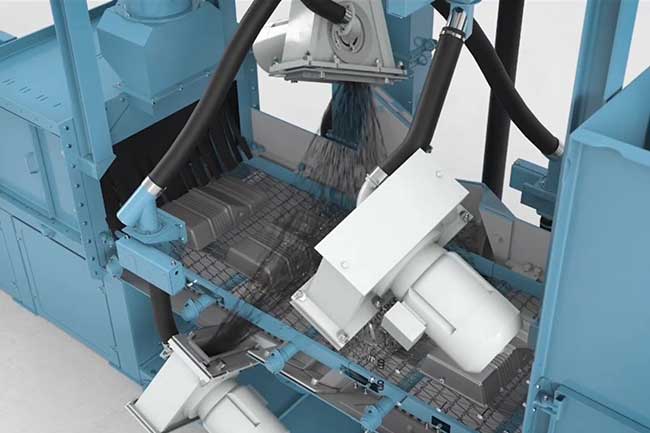

RT type Table Shot Blast Machine

Updated: August 13, 2025

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

BlastKing’s table blasting machines are designed and built as fully integrated blast cleaning systems to handle larger and/or more fragile castings than barrel machines.

Superior design, quality and rugged construction make the BlastKing Machines more reliable and easier to maintain than other machines.

Features

- Proven ORICA® double-disc blast wheels with the inclined layout

- Various numbers of wheels are possible

- Automatic PLC control

- Extremely compact design, minimum floor space required

- Totally self-contained, includes dust collector, separator, cartridge filtration system

- No foundations required, no extra ducting needed

- Clamshell door design allows easy loading with truck or crane

- Full safety interlocks

- Low noise levels

Applications

- Rust and heat scale removal

- Paint stripping

- Surface texturing

- Preparation for painting, bonding and plating

- Corrosion removal

- Deburring, deflashing

- Cleaning

- Cosmetic finishing

Key Benefits

High Performance Table Shot Blaster

The applications of Rotary table blast machines are mainly for targeted blast cleaning of single/multiple workpieces producing repeatable cleaning results. Placed workpieces on the slowly rotating table, the workpieces are exposed to blast stream from the turbine(s) located on the wall & ceiling of the machine housing.

The shot blast process can occur in single batch mode or indexing with multiple batches placed on the rotary table. Depending on the processing mode, the table is open over 360 degrees or divided into different segments. The layouts of the blast wheels on the table-type blasting machine are mainly according to the features of the parts.

Working Video

Basic Specification

| ITEM | RT1000/900 | RT1200/900 | RT2000/1500 |

|---|---|---|---|

| Maximum dimension of chamber (mm) | Φ1350×560 | Φ1350×860 | Φ2654×560 |

| Maximum workpiece weight (kg) | 400 | 400 | 1000 |

| Diameter of Turn Table(mm) | Φ1200 | Φ1200 | Φ2500 |

| Number of blast wheels and power (kw) | 11 | 2×7.5 | 2×15 |

| Overall dimension (mm) | 1500×3450×3780 | 1900×3450×4160 | 4260×3647×5366 |

| Material of table | Manganese | Manganese | Manganese |

| Ventilation requirements (m3/h) | 4000 | 6000 | 8000 |

| Material of Protective lining | Manganese/Cast alloy | Manganese/Cast alloy | Manganese/Cast alloy |

| Material of blast chamber | Mild steel | Mild steel | Mild steel |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685