Boosting Productivity: How Roller Conveyor Shot Blasting Machine Takes Surface Cleaning to the Next Level

Discover the power of Roller Conveyor Blasting Machines in revolutionizing surface cleaning. Learn about their benefits, applications, factors to consider, best practices, and the exciting advancements shaping the future.

Updated: January 25, 2025

1. Introduction

When it comes to surface cleaning, productivity and efficacy are crucial for a smooth production process. Traditional methods of surface cleansing can be labor-intensive and time-consuming, leading to bottlenecks and delays. However, the introduction of roller conveyor type shot blasting devices has revolutionized the surface cleaning industry due to technological advancements. In this article, we will examine how roller conveyor shot blasting machines are revolutionizing the cleaning of surfaces, delivering superior results, and increasing productivity in a variety of industries.

Get A Strong Partner at Your Side Now!

Get Your Instant QuoteBlastKing’s ability to improve your business profitability is based on more than 40 years’ experience and a spirit of innovation.

2. Understanding Roller Conveyor Type Shot Blasters

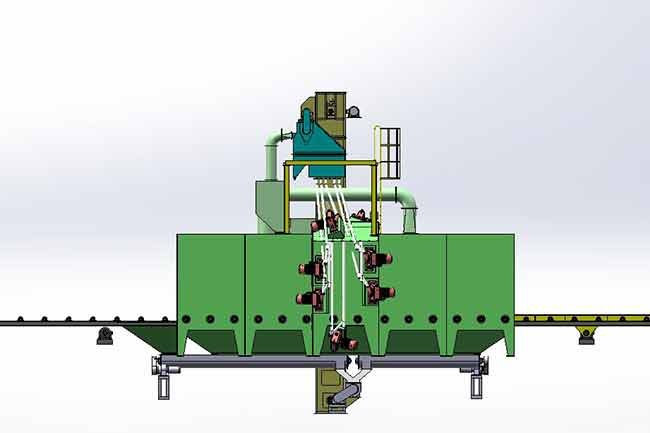

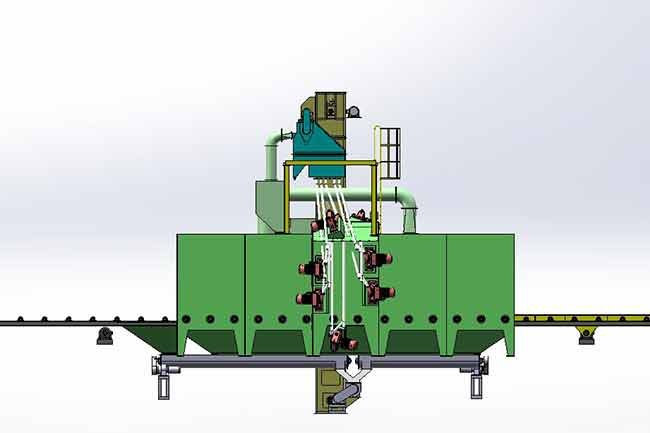

Roller conveyor sand blasting machines are specialized tools designed to clean and prepare surfaces by propelling abrasive particulates at the material at high velocity. This technique, known as shot blasting, effectively removes corrosion, scale, paint, and other contaminants, leaving the surface clean, roughened, and ready for further processing or coating.

A conveyor system with rollers transports the workpieces through the blasting chamber on these devices. Multiple blast wheels positioned strategically direct the abrasive media onto the surface as the workpieces travel through, ensuring thorough cleaning and consistent results.

3. Benefits of Roller Conveyor Shot Blasting Machines

3.1. Increased Cleaning Efficiency

The ability of roller conveyor shot blasting machines to clean a large number of workpieces in a brief period of time is one of their primary advantages. The conveyor system’s continuous movement enables a continuous cleansing process, eliminating the need for manual handling and drastically reducing cleaning time. This increased efficacy results in increased output and productivity for businesses.

3.2 Consistent and Uniform Surface Preparation

Using shot blasting devices with a roller conveyor, surface preparation becomes highly consistent and uniform. The controlled blasting procedure ensures that each piece of work receives the same level of cleaning, eliminating surface quality variations. This uniformity is essential for subsequent processes such as coating and painting, as it ensures optimal adhesion and durability.

3.3 Reduced Downtime

Traditional surface cleaning methods frequently require manual labor, which can result in frequent downtime and frequent interruptions. Shot blasting devices with a roller conveyor reduce downtime by automating the cleaning process. While the machine operates continuously, workers can concentrate on other tasks, resulting in increased overall productivity.

3.4 Enhanced Worker Safety

Safety of employees is a top priority in every industrial context. Roller conveyor shot blasting machines create a safer workplace by minimizing direct exposure to hazardous materials and repetitive manual labor. By automating the cleaning process, employees are safeguarded from the dangers associated with manual cleaning methods.

4. Applications of Roller Conveyor Shot Blasting Machines

Roller conveyor automatic shot blasting machines are utilized in industries requiring effective and high-quality surface cleansing. Among the industries where these devices are used extensively are:

4.1 Automotive Industry

Roller conveyor shot blasting machines are utilized in the automotive industry to clean and prepare vehicle bodies, chassis, and other automotive components. These devices effectively eliminate rust, scale, and old paint, thereby preparing the surface for painting and coating processes. Utilizing roller conveyor shot blasting devices guarantees the production of long-lasting and high-quality automotive components.

4.2 Steel Manufacturing

Numerous processes in steel fabrication necessitate clean and well-prepared surfaces. The removal of mill scale, rust, and other contaminants from steel plates, profiles, and structural components is vitally dependent on roller conveyor shot blasting devices. The cleansed surfaces provide superior adhesion for coatings and subsequent processing, resulting in steel products of superior quality.

4.2 Foundries and Forging

Roller conveyor shot blasting equipments are utilized in foundries and forging operations to clean castings, forgings, and molds. These devices efficiently eliminate sand, scale, and other residues, thereby enhancing the surface quality of the cast and forged parts. The surfaces’ cleanliness facilitates subsequent machining and refining processes, resulting in a higher quality product overall.

5. Factors to Consider When Choosing a Roller Conveyor Sand Blasting Machine

Several factors should be considered when selecting a roller conveyor sand blasting machine to ensure optimal performance and suitability for specific applications. These elements include:

5.1 Size and Capacity

Size and capacity of the roller conveyor shot blasting machine should correspond to the dimensions and volume of the to-be-cleaned workpieces. It is crucial to select a machine that can accommodate the necessary throughput without sacrificing cleansing quality.

5.2 Blast Media Compatibility

For effective cleaning of various materials and surfaces, specific varieties of blast media are required. To accomplish the desired cleaning results, compatibility between the blast media and the roller conveyor shot blasting machine is essential.

5.3 Control Systems and Automation

Advanced control systems and automation features can substantially improve the usability and performance of shot blasting machines with roller conveyors. Consider purchasing devices with user-friendly interfaces, programmable settings, and real-time monitoring capabilities for enhanced control and operability.

5.4 Maintenance and Service

Regular maintenance is required to maintain the roller conveyor shot blasting machine in prime condition and to prolong its life. Consider the availability of spare parts, technical support, and service options when choosing a machine to ensure minimal interruption and long-term dependability.

6. Best Practices for Operating Roller Conveyor Shot Blasting Machines

In order to maximize the benefits of roller conveyor shot blasting machines, it is necessary to adhere to certain best practices during operation. These practices consist of:

6.1 Proper Loading and Unloading Techniques

Ensure that workpieces are loaded securely and uniformly onto the conveyor system. To prevent injury to the cleaned surfaces and ensure a smooth workflow, proper unloading techniques must also be implemented.

6.2 Adjusting Blast Parameters for Optimal Cleaning

For various surfaces and contaminants, the blast parameters, such as blast media type, velocity, and angle, can be modified to accomplish the desired cleaning results. By conducting experiments and adjusting the parameters, the cleaning process can be optimized and productivity increased.

6.3 Regular Maintenance and Inspection

Routine maintenance and inspection are essential for keeping the roller conveyor shot blasting machine in top shape. Regularly inspect and clean the blast wheels, replace worn-out components, and lubricate them to prevent malfunctions and maintain consistent performance.

6.4 Training and Safety Measures

Operators should receive proper training to ensure that they are conversant with the machine’s operation and safety procedures. Always observe adequate safety measures, such as donning personal protective equipment and adhering to established guidelines.

7. The Future of Surface Cleaning: Advancements in Roller Conveyor Flatbed Shot Blasting Machines

Roller conveyor automatic shot blasters are poised for further development as technology evolves. Future advancements may include improved automation features, integration with intelligent systems, and the use of explosion media that is less harmful to the environment. These innovations will further expedite the process of surface cleaning, increase productivity, and reduce environmental impact.

8. Conclusion

Roller conveyor automatic blasting machines have revolutionized surface cleansing by providing efficient and consistent results while increasing industry productivity. Their ability to clean large quantities of workpieces swiftly and uniformly, combined with the numerous advantages they provide, makes them an indispensable asset for companies seeking to optimize their production processes. By investing in the appropriate roller conveyor shot blasting machine and implementing best practices, businesses can achieve superior surface cleansing and increase their overall productivity.

FAQs

FAQ 1: Are roller conveyor shot blasting machines suitable for delicate materials?

Yes, shot blasting devices with roller conveyors can be adjusted to accommodate delicate materials. By selecting the proper blast parameters and employing gentle blast media, these machines are able to clean delicate surfaces without causing injury.

FAQ 2: How often should maintenance be performed on a roller conveyor pass-through shot blasting machine?

Regular maintenance should be performed according to the manufacturer’s recommendations. Daily or at regular intervals, routine inspections and cleansing should be performed, while more extensive maintenance tasks can be scheduled monthly or quarterly.

FAQ 3: Can roller conveyor shot blasting machines be customized for specific applications?

Yes, roller conveyor through-type shot blasting machinery can be modified to meet application-specific specifications. Frequently, manufacturers offer customizable options for blast wheel configuration, conveyor speed, blast media recovery systems, and other features.

FAQ 4: What safety precautions should be taken when operating a roller conveyor shot blasting machine?

To minimize exposure to abrasive media, operators should don appropriate personal protective equipment, such as goggles, gloves, and protective clothing. Additionally, they should adhere to safety protocols and receive appropriate training on the operation of the machine and emergency procedures.

FAQ 5: How can roller conveyor shot blasting machines contribute to a sustainable manufacturing process?

Shot blasting devices with a roller conveyor contribute to sustainability by reducing chemical use and waste production. The efficient cleaning procedure eliminates the need for environmentally hazardous solvents and reduces the disposal of hazardous materials, thereby promoting an eco-friendly manufacturing process.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!