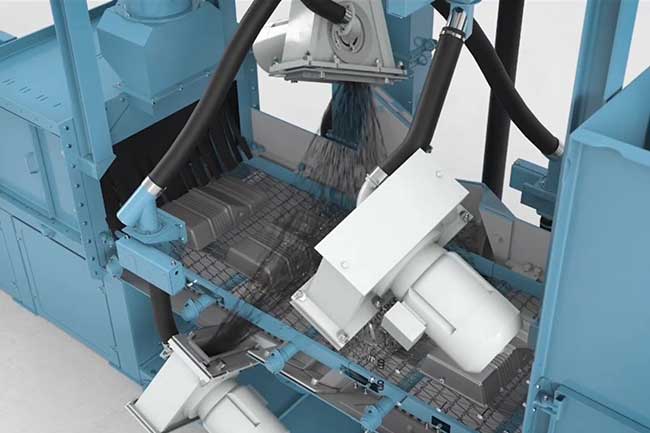

Pipe Shot Shot Blasting Machine

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

BlastKing designs and manufactures fully automated pipe blast machines for internal and external surface profiling and removing rust and mill scale from steel pipe. The pipe must be cleaned and dust-free prior to the coating process.

BlastKing works with customers to determine their requirements and will consider many factors, including:

- Steel abrasive types

- Profile requirements

- Surface cleaning requirement

- Line speed requirement

- BlastKing works closely with coating manufacturers to assure proper mill profile is achieved to give the best adherence of coating.

Technically speaking, BlastKing’s internal pipe blasting equipment is divided into air blasting equipment and wheel blasting equipment. the air blasting equipment is mainly for small pipes which a diameter under 700mm, and it can blast processing up to 8 pieces at one time by with automatic pipe handling systems. the wheel blasting equipment is mainly for big pipes which a diameter above 500mm, and it can only blast cleaning one piece at a time.

The pipe external shot blasting machine is conveyed through the wheel shot blasting machine on a specially designed external skew roll/wheel type material handling system. An extensive range of high production blast cabinets is available to handle from 5cm (2″) to 366cm (144″) diameter pipe at variable cleaning speeds.

BlastKing pipe machines include an air wash and dust collection system that work together to remove contaminants and fines, control dust, and maintain correct abrasive size.

Working Video

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685