Shot Blasting Machine for Interior Pipe (ID 500mm to 3000mm)

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

BlastKing pipe auto blasting machines are fully automated systems designed to remove rust, scale, welding slags, contaminants, old paint, et cetera, from heating & drainage pipelines and oil & gas pipelines.

But it also can reduce the internal surface stress. Thus, this kind of equipment can significantly increase the service life of the steel pipe and reduce the internal corrosion of the steel pipe, thereby improving the intrinsic and appearance quality of the steel pipe.

1. Features

-

Blast processing pipe internal diameter range from 700mm to 3000mm

-

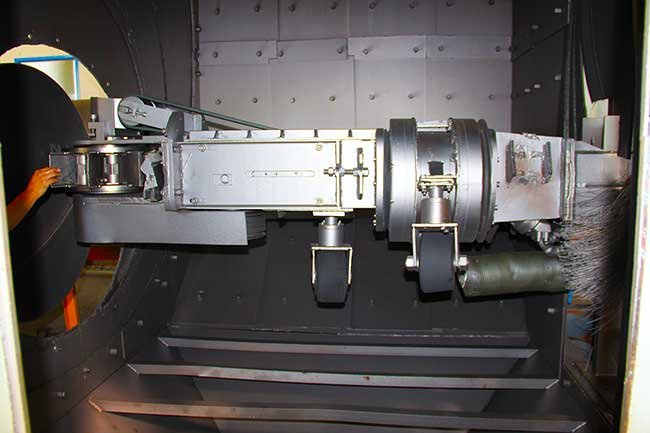

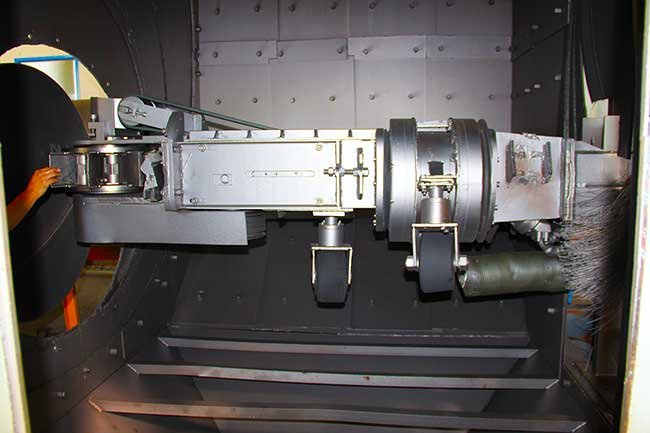

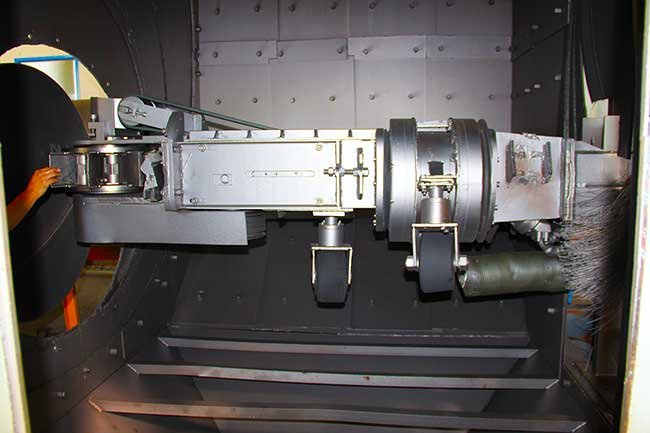

Specially designed hydraulic-driven blasting turbines which function consumption ratio up to 18kg/min·kw.

-

Easy for blast processing, low maintenance cost.

-

Less intensity of labor.

-

Interlocks and protect detection measures.

-

Maximum energy utilization by use of adjustable abrasive stream guide plates

2. Applications

This auto shot blasting machine is mainly designed for blast processing big pipes like heating & drainage pipelines and oil & gas pipelines, etc.

-

Remove rust, scale, welding slags, contaminants, old paint, etc.

-

Reduce the internal surface stress.

-

Reduce the internal corrosion of the steel pipe.

-

Increase the pipe service life.

3. Key Benefits

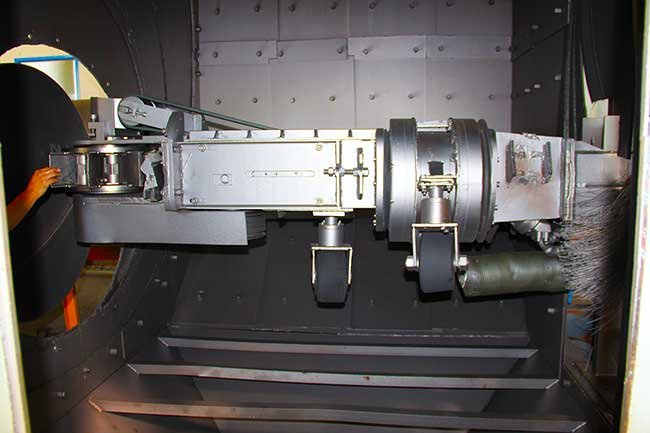

4. Pipe Internal Blasting Machine Composition

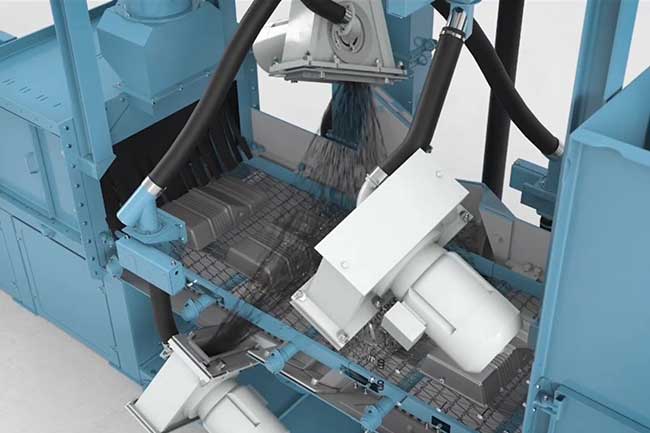

The equipment mainly consists of front and rear movable sub-chamber, fixed sealing chamber, inner wall hydraulic movable blasting turbine steel pipe self-pass device, belt machine type projectile conveying mechanism, bottom belt conveyor, elevator, maintenance platform, separator, dust removal system, inner wall blasting turbine walking mechanism, steel pipe on the discharge mechanism, hydraulic system and electric control system, etc.

The front and rear movable sub-chamber and fixed sealing chamber use high manganese steel liner which thickness up to 12mm.

5. Working Video

6. Basic Specification

- Pipe diameter: 400mm to 3000mm

- Hydraulic Turbines power: 110Kw

- Blast processing speed: 05m/min to 3.5m/min

- Abrasive flow rate: 300kg/min to 800kg/min

- Total power consumption: approx. 240kw

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685