Multi-purpose Auto Blasting Machine

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

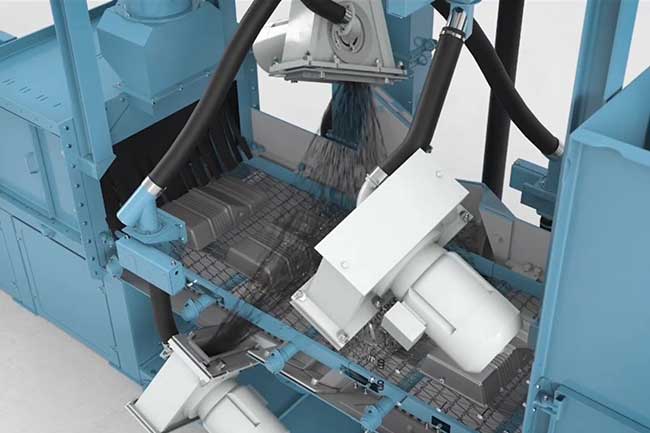

The G-type shot blasting machine range demonstrates the highest performance variants of this machine type for blasting pipes, sheet metal, beams and profiles.

Roller conveyors are predominantly used to clean pipes, metal plates, beams, and profiles in a continuous through-feed process.

BlastKing offers a variety of roller conveyors for different uses and work speeds. The Type G range is mainly designed for the treatment of metal plates, beams, or profiles in the steel construction or steel preparation industries. The machines can be delivered as standalone units or integrated into automatic transportation or sawmill/bore line.

1. Features

- Proven ORICA® double-disc blast wheels with the inclined layout

- Various numbers of wheels are possible

- Integrated filter unit possible – depends on machine size

- abrasive removal device

- Automatic PLC control

- Workpiece recognition

- Can even be used as a “Universal Blasting Machine” for sheet metal, profiles, and welded constructions

2. Applications

G-type roller conveyor shot blasting machines are universal shot blasting units, which designed to meet the user’s blast processing requirements for pipes, beams, profiles, metal sheets, etc. auto blasting cleaning.

- Remove rust, welding slag, oxide, rust and heat scale, old paint, and other debris.

- Improve the fracture resistance of the surface.

- Improve the corrosion resistance and the fatigue resistance, intrinsic quality.

- Prolonging service life.

3. Key Benefits

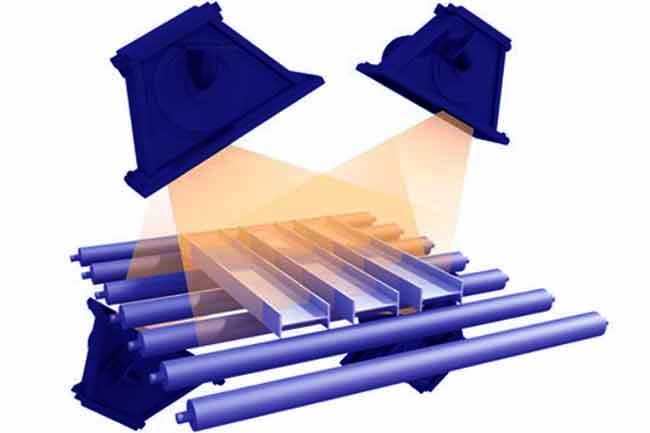

4. Pipe Shot Blasting Machine with New ORICA Turbines

The G-type roller conveyor range demonstrates the highest performance variants of this machine type for blasting sheet metal, beams, and profiles.

The main difference between this machine to others offered in the marketplace is the angled arrangement of the blast wheels on the top of the machine. This arrangement reduces the accumulation of abrasive on the sections of longer profiles. By using this method a significantly larger percentage of the blasting energy is used on the main task, i.e. de-rusting and scale removal from sheet metal and profiles, and avoids creating piles of abrasive.

5. Working Video

6. Basic Specification

| TYPE | KB 600G | KB 1000G | KB 1500G | KB 2000G | KB 2500G | KB 3000G | |

|---|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 700 | 1100 | 1600 | 2200 | 2600 | 3300 | |

| Machine entrance height (mm) | 550 | 550 | 550 | 550 | 550 | 550 | |

| Work speed (m/min) | 0.5-2.3 | 0.5-2.4 | 0.5-2.3 | 0.5-2.5 | 0.5-3.0 | 0.5-2.5 | |

| Number of blast wheels | 4 | 4 | 4 | 4/6 | 6/8 | 6/8 | |

| Power per blast wheel (kw) | 7.5 | 7.5/11 | 11/15 | 11/15 | 11/15/18.5 | 11/15/18.5 | |

| Roller pitch (mm) | 800 | 650 | 650 | 800 | 800 | 800 | |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685