Blasting Machine for PEB Beams, Channels, Steel Plates, etc.

Updated: August 13, 2025

Ready to boost your PEB beam game? Discover how automated shot blasting machines make surface prep faster, easier, and more cost-effective. Dive in now!

Outline

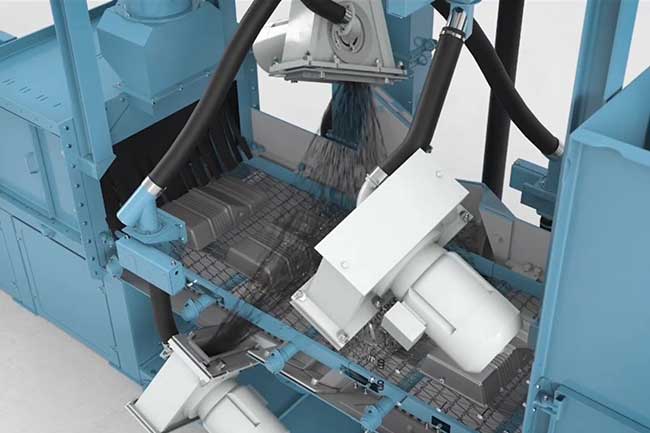

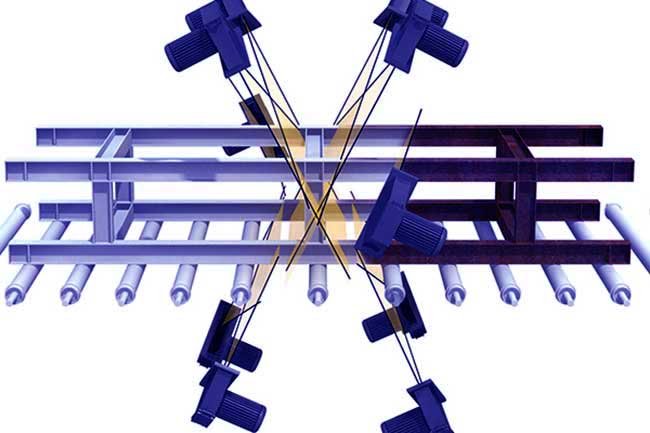

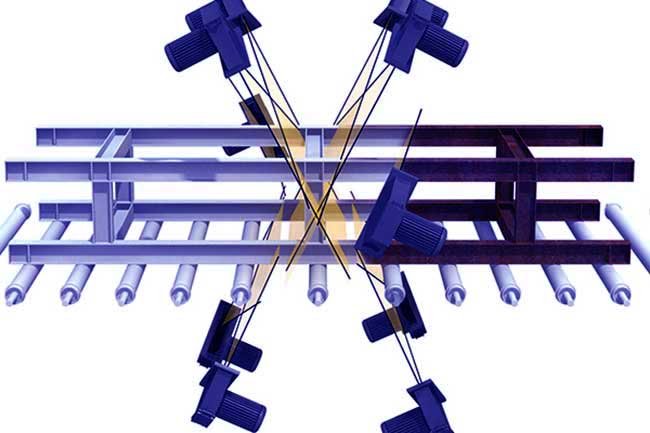

Beam blasting machines with roller conveyor X Type differentiates themselves from the Type G and Type HD roller conveyors by the shot blast wheels being installed at an angle to the direction of movement through the machine.

The angled positioning of the shot blast wheels ensures that the blasting operation is perfect, especially on parts such as H beams, I beams, PEB beams, PEB columns, profiles, sections, etc.

1. Features

- Proven ORICA® double-disc blast wheels with the inclined layout

- Various numbers of wheels are possible

- Integrated filter unit possible – depends on machine size

- abrasive removal device

- Automatic PLC control

- Workpiece recognition

- Can even be used as a “Universal Blasting Machine” for sheet metal, profiles, and welded constructions

2. Applications

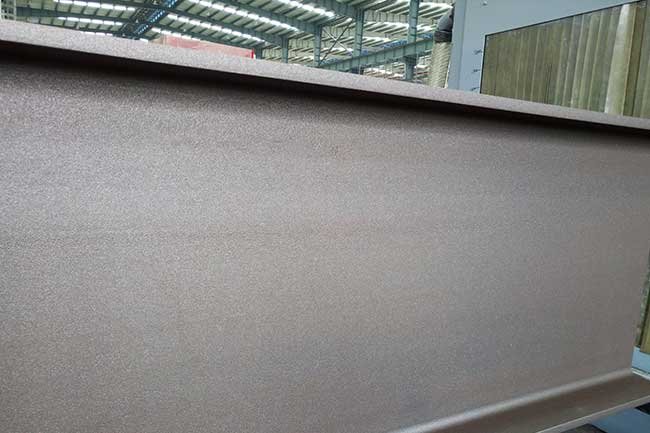

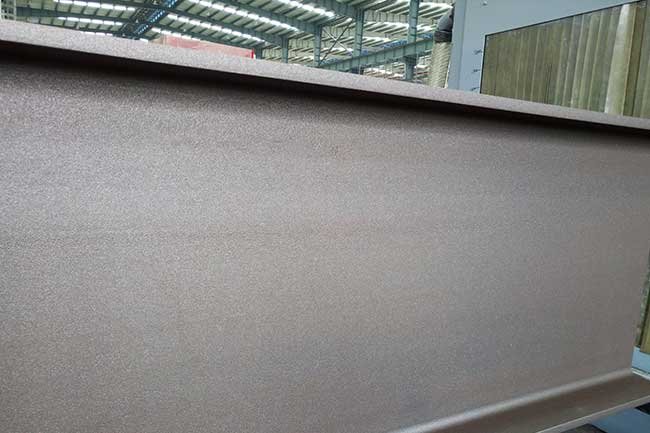

For the treatment of, steel fabrication, PEB beams, plates, and profiles in the steel manufacturing and processing industry.

- Cleaning

- Corrosion removal

- Paint stripping

- Rust and heat scale removal

3. Key Benefits

4. Auto Blasting Machine for Construction

X type construction shot blasting machine is a new type of special equipment designed and made according to the features of fabrication, construction, beams and PEB beams, it is multi-functional blasting equipment to remove the rust layer, weld slag, and oxidized skin, so as to obtain a uniform and consistent metallic luster, in order to improve the quality of steel coating and anti-corrosion effect.

The shot blasting machine can also be used as a “Universal Blasting Machine” for sheet metal, profiles, and welded constructions.

5. Working Video

6. Basic Specification

| Type | KB 8/10X | KB 1/15X | KB 16/16X | KB 1/18X | KB 12/22X | KB 15/22X |

|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 800 | 1000 | 1600 | 1000 | 1200 | 1500 |

| Machine entrance height (mm) | 1000 | 1500 | 1600 | 1800 | 2200 | 2200 |

| Work speed (m/min) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Number of blast wheels | 4 | 6 | 6/8 | 6/8/12 | 12/16 | 12/16 |

| Power per blast wheel (kW) | 7.5/11/15 | 7.5/11/15 | 11/15 | 11/15 | 11/15 | 11/15 |

| Roller pitch (mm) | 800 | 800 | 800 | 800 | 800 | 800 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685