Pass-through Tunnel Blasting Machines

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Outline

The constant traveling speed of the workpieces ensures that the tunnel-type shot blasting machine can be easily and smoothly integrated into an existing production line.

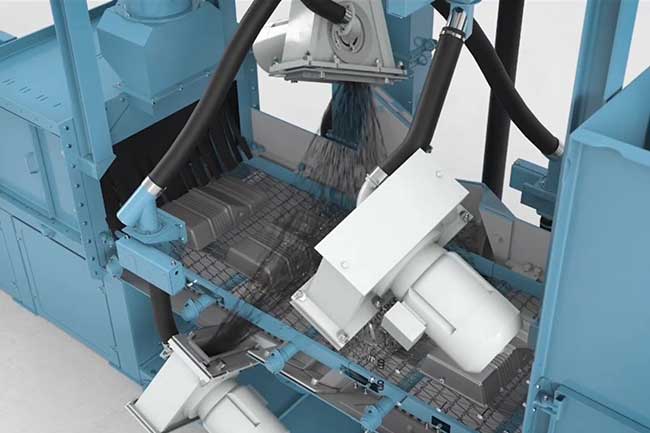

The ability to adapt the moving speed of the workpiece and the wheel power ensures that the machine can be easily and smoothly integrated into an existing production line. Maximum coverage of the workpiece is achieved by the blast wheels being arranged in an “X” alignment, diagonally to the moving workpiece. In this formation, the leading edges of complex components, welded sections, and flame-cut parts can be thoroughly blasted.

1. Features

- Proven ORICA® double-disc blast wheels with the inclined layout

- Various numbers of wheels are possible

- Latest transport technology

- Highly efficient blast wheels

- Short blasting times

- Multiple machine sizes and variations

2. Applications

Removal of mill and forge scale as well as rust

Blasting of steel constructions as pre-treatment before painting

Removal of burrs and flashes

Increase of surface roughness

Removal of moulding sand and residues

3. Key Benefits

4. Tunnel Auto Blasting Machine

The workpieces are carried on rotating hooks on the Manually operated monorail or conveyed automatically on a (optional) Power & Free conveyor to the blast cabinet where they are blasted by blast wheels. The blast cycle runs in accordance with the preset blast time. When the blast wheels stop, the door is opened and the hook exits automatically.

The transport speed or index time can be coordinated to the blast wheel power and surface finish required. The system can be easily extended to suit factory layout and integrated with pre-and post-blast operations.

5. Working Video

6. Basic Specification

| Machine type | BK3-6C | BK5-12C | BK8-20C | BK10-25C | BK12-30C |

|---|---|---|---|---|---|

| Max. Piece Dia. x Height (mm) | 300*600 | 500*1200 | 800*2000 | 1000*2500 | 1200*3000 |

| Max Height of Chamber(mm) | 4700 | 5900 | 6700 | 7200 | 7700 |

| Max Width of Chamber (mm) | 4200 | 5100 | 5900 | 6100 | 6300 |

| Max Length of Chamber (kg) | 5000 | 8500 | 8500 | 10500 | 10500 |

| No. of Wheels x Power (KW) | 4x 7.5 | 8x7.5 | 12x11 | 12x 11 | 12x 11 |

| Total Installed Power(KW) | 41 | 72 | 143 | 147 | 157 |

| Exhausted Air Quantity (m3/h) | 6000 | 12000 | 18000 | 22000 | 25000 |

| Foundation Pit | Yes | Yes | Yes | Yes | Yes |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685