Steel Plate Shot Blasting Machine Manufacturer

Updated: August 30, 2025

Experience unprecedented efficiency and precision with BlastKing’s cutting-edge automated shot blasting machine, equipped with a roller conveyor system designed for steel plates, beams, profiles, and more.

Outline

1. What Is The Steel Plate Shot Blasting Machine?

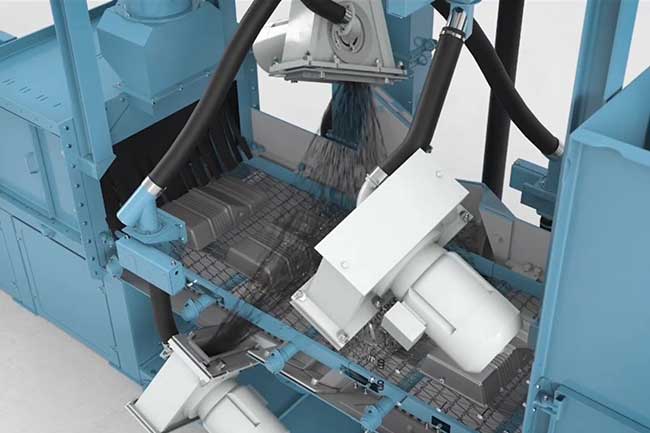

BlastKing’s steel plate shot blasting machine with roller conveyor system is primarily employed for cleaning steel plates, profiles, and beams in a continuous through-feed process, making it especially suitable for integration into fully automatic production lines.

What sets this steel plate shot blaster apart from others available in the market is the angled arrangement of the shot blast wheels located on the top of the machine. This specific configuration minimizes the accumulation of abrasive on sections of longer profiles. By adopting this method, a significantly larger portion of the blasting energy is directed toward the primary task, which is the removal of rust and scale from sheet metal and profiles. This approach also helps prevent the formation of abrasive piles.

Transforming Workflows: Boost Productivity with Automated Steel Plate Blasting Excellence!

Tired of variations in surface treatment quality?

Say goodbye to manual labor woes. Our state-of-the-art shot blasting solution streamlines operations, ensuring faster turnaround times and impeccable results for beams, steel plates, profiles, and beyond.

Call us today at +86 135 8931 7685

2. Features

- Utilizes ORICA® double-disc blast wheels with an inclined layout, ensuring proven performance.

- Configurable with various numbers of blast wheels to meet specific application requirements.

- Option for an integrated filter unit, dependent on the machine size.

Equipped with an abrasive removal device for enhanced operational efficiency. - Incorporates automatic PLC control for seamless and precise operation.

Features workpiece recognition capabilities for improved customization. - Suitable for very thick plates, thanks to the higher loading capacity of the rollers.

- Boasts perfect lining and a specialized roller track, ensuring an extended machine lifespan.

3. Applications

Cleaning: The G type roller conveyor shot blasting machine is highly effective in thoroughly cleaning steel surfaces, removing contaminants, residues, and other impurities that may compromise the quality of the material.

Corrosion Removal: This machine is specifically engineered to tackle corrosion on steel plates, profiles, and beams, ensuring the restoration of the material to its optimal condition.

Paint Stripping: For projects requiring the removal of old or unwanted paint coatings, the G type roller conveyor shot blasting machine provides a precise and efficient solution, preparing surfaces for subsequent treatments or coatings.

Rust and Heat Scale Removal: The machine excels in eliminating rust and heat scale, enhancing the structural integrity of steel components by addressing issues related to oxidation and heat-induced scale.

Safeguarding Success: Ensure Durability and Longevity in Every Blasted Product!

Fed up with constant machine breakdowns?

Invest in reliability. Our automated shot blasting machine, tailored for beams, steel plates, profiles, etc., not only enhances efficiency but also ensures the durability and longevity of your finished products.

Call us today at +86 135 8931 7685

4. Key Benefits

5. Choosing the Right Automated Steel Plate Shot Blasting System

Our G type roller conveyor shot blasting machine is designed for versatile applications in the steel manufacturing and processing industry, specifically tailored for the treatment of steel plate, steel fabrication, beams, pipes, and profiles. This robust machine excels in various surface preparation tasks, making it an indispensable tool for enhancing the quality and durability of steel components.

G-type shot blast machines are principally fitted with the latest version of the ORICA angled turbines blasts between 5 and 20% quicker than a roller conveyor with shot blast wheels that are installed straight.

After the blasting process, the workpiece may still be covered in blast media, which must be cleaned off. This task is carried out by a rotating brush and a high pressure blow-off station, which will clean off any media remaining.

6. Working Video

7. Basic Specification

| TYPE | KB 600G | KB 1000G | KB 1500G | KB 2000G | KB 2500G | KB 3000G |

|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 700 | 1100 | 1600 | 2200 | 2600 | 3300 |

| Machine entrance height (mm) | 550 | 550 | 550 | 550 | 550 | 550 |

| Work speed (m/min) | 0.5-2.3 | 0.5-2.4 | 0.5-2.3 | 0.5-2.5 | 0.5-3.0 | 0.5-2.5 |

| Number of blast wheels | 4 | 4 | 4 | 4/6 | 6/8 | 6/8 |

| Power per blast wheel (kw) | 7.5 | 7.5/11 | 11/15 | 11/15 | 11/15/18.5 | 11/15/18.5 |

| Roller pitch (mm) | 800 | 650 | 650 | 800 | 800 | 800 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685

8. How Does The Metal Sheet Shot Blasting Machine Work?

The processed items smoothly traverse the machine on roller conveyors. Turbines, constructed from wear-resistant materials and boasting a power range of 5.5 – 45 kW, guarantee efficient shot blasting. Positioned in the blasting area, the machine’s robust housing is shielded from wear by a layer of manganese steel. Seals in the inlet chamber, featuring a series of rubber curtains, and the outlet chamber, facilitate cleaning, retaining the abrasive within the machine.

To ensure the removal of abrasive from the material post-shotblasting, rotating brushes and a high-pressure fan come into play just before the material exits the machine. The inclusion of a screw conveyor, elevator, and abrasive cleaner enables the recovery and continuous cleaning of the abrasive. Standard equipment for the machine comprises a Siemens PLC, display, automatic or manual mode, automatic turbine start, working hour counter, and a frequency converter for roller drive, among others.

In addition to the aforementioned machines, our product line includes skew roll shot blasting machines designed without notches. These are ideal for shot blasting bar material, pipes, gas cylinders (conical rollers), containers, and special machines tailored to meet specific customer requirements. Our shot blasting and priming machines can be seamlessly integrated, along with a drying chamber, an automatic painting chamber, and a drying tunnel, forming a highly productive line for applying primer.

Effortless Mastery: Master the Art of Metal Plate Blasting with Cutting-Edge Automation!

Struggling with complex shot blasting setups?

Unlock the full potential of your blasting processes. Our modularly designed machines, coupled with a roller conveyor system, empowers your team to achieve mastery in shot blasting for beams, steel plates, profiles, and more – effortlessly.

Call us today at +86 135 8931 7685