FAQ - Frequently Asked Questions

Shotblasting-Frequently Asked Questions

Q.1 What is shot blasting?

The shot blasting process is carried out to prevent metal fatigue or to crack and for cleaning and surface hardening. In this method, the role of the shot is to remove impurities, rust, scattered pieces of rubbish, or remains that may affect metal strength. It is environment-friendly and a rapid cost-effective surface finishing method that is used for cleaning, polishing metal, and other surfaces by applying a high-speed stream of shots.

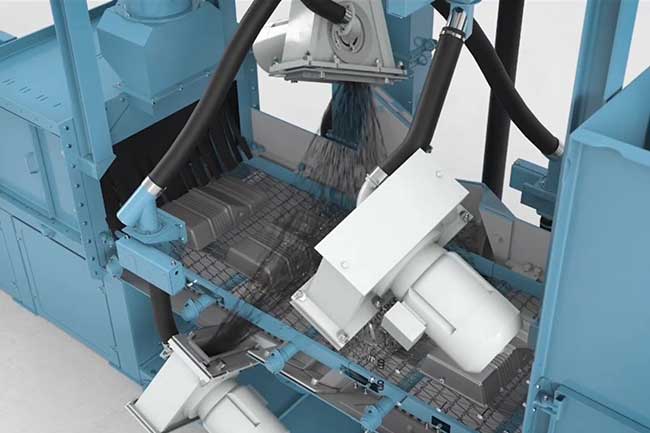

Q.2 What is shot blasting machine?

A shot blasting machine is a mechanical method of propelling abrasive using a centrifugal wheel to remove surface and other impurities from the surface of steel applications. General, blasting prior to finishing serves three primary purposes:

- It cleans and descales surfaces

- Adds texture to enhance paint adhesion

- Properly reduces maintenance costs by increasing coating life

Q.3 What is sandblasting?

Sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface and shape a surface, or remove the surface contaminants.

Q.4 What Is the Purpose of Sandblasting?

Sandblasting can thoroughly clean and prepare a surface for painting. This process is for spraying sand at a high velocity toward the intended surface remove stubborn dirt, grime, and other matter. Meanwhile, it is also an ideal technique for concrete, brick, stucco, and other surfaces.

Q.5 What are the useful effects of Shot Blasting Machines’ Blasting?

Shot blasting machines’ blasting benefits are as follows:- It provides higher production rates, wider abrasive selection and better blast pattern accuracy.

- The finished surface obtained is absolutely free from chemical deposits, scales, and dust content.

- Shot blasting facilitates the formation of a permanent bond between the protective coat (zinc, paint, or epoxy) and the shot blasted surface. It also helps to detect surface faults or defects.

- It eliminates the usage of non-ecofriendly and harsh chemicals.

- Increases longevity and durability of protective surface coats as it adheres better to the shot blast cleaned and scale-free surface.

Q.6 What is difference between shot blasting and sandblasting?

Sandblasting and shot blasting both are processes that are being utilized in mechanical surface cleaning. Many industries that use metal apply these methods in daily practices for removing of corrosion, paint, and other films and preparing the surface for coating. In both methods, cast-iron work is also blasted to remove old paint layers. But the differences between both processes are only for principle and application types.

Q.7 What type of material does the abrasive consist of?

For turbine wheel shot blasting, the abrasive material used consists of 90% steel due to the high energy with which the abrasive is ejected onto the workpiece surfaces. Round cast steel shot material ranging from 0.8 to 1.5 mm in diameter is often used. Angular cast steel shot material or sections of wire mesh can also be used. The required surface finish determines what type of abrasive should be used.

Q.8 How do you clean the abrasive?

A cascade wind sifter is used for most applications. The abrasive is distributed and guided so that it forms a fine mist/veil. This is achieved by having the abrasive trickle over a wide edge. A cartridge filter unit generates a flow of air through the mist of abrasive material. Fines such as broken grain and dust are thus removed from the abrasive and separated via an impact separator and/or filter cartridges. In special cases like in foundries, for example, a magnetic sifter is fitted upstream of a cascade sifter and used to separate the abrasive metal material from the sand and discharge it.

Q.9 To where does BlastKing deliver?

BlastKing delivers worldwide to over 50 countries on all continents. BlastKing’s customers can be found in a wide range of industrial sectors. This includes foundries, forges, the machine-building sector, and the auto industry, for example.

Q.10 What sets BlastKing apart from its competitors?

First and foremost, there is the expertise of BlastKing employees. Shot-blasting machines are our passion. We develop custom solutions for all of the tasks our customers have to handle in the field of turbine-wheel shot-blasting. This knowledge is also incorporated into the design of standard machinery. The combination of older, more experienced employees with young colleagues from a variety of branches enables us to always find a suitable solution. Furthermore, we have modern design and manufacturing facilities at our disposal. Thanks to our longstanding expertise, we are familiar with each and every part of our machines. This enables us to recognize and eliminate weaknesses early on. We are building machines that are made to last. And this keeps us busy working in two to three shifts. We build machines that are robust and easy to use and maintain.

Q.11 What product lines does BlastKing offer?

Apart from new machines, BlastKing also offers pre-owned shot-blast machines. These are adapted to meet the spatial requirements and quality standards of the customer. BlastKing’s third product line involves the supply of spare and wear parts and the performance of inspection and repair tasks of turbine-wheel shot-blast machines of various manufacturers.

Q.12 Where does BlastKing Manufactue?

BlastKing’s shot-blast machines are manufactured in the Qingdao plant in China. This is also where experienced and competent employees work in compliance with quality specifications set out by BlastKing.

Q.13 Who should I contact if there’s a technical problem?

Please either call the reception desk at the BlastKing plant in Qingdao, China at 0086 159 6328 1021 or send an e-mail to info@blastkinggroup.com for immediate assistance.

Q.14 How long will it take to receive a spare and wear parts order?

Close to a third of all spare part orders is delivered the following day. Should delivery take longer, you will be notified promptly of when to expect the shipment.

Q.15 What do BlastKing’s Services comprise?

BlastKing’s customer services aim to provide prompt delivery of spare and wear parts, to give advice and implement modernisation and output increase measures for blasting machines, to offer remote maintenance and repair services, as well as consultation, instruction, and training services.

Q.16 What makes shot-blast machines from BlastKing better than others?

An essential difference is the turbine and filter technology. BlastKing’s high-performance turbines are robust and require little maintenance. Moreover, BlastKing’s shot-blast machines are capable of a high abrasive shot flow rate while requiring the same amount of energy as other turbines. They offer high economic efficiency as a result. The filter cartridges can be easily pulled out and replaced in the clean gas area. Installation tasks require no time-consuming nut and bolt fittings. The machine features a robust and solid design made for long service life. The blasting chambers are made of manganese carbon steel. Generously dimensioned service openings facilitate and expedite the performance of servicing tasks. In the end, it is the concept that wins over many customers.

Q.17 What is the advantage of high-performance turbines from BlastKing?

BlastKing’s high-performance turbines are robust and require little maintenance. Moreover, BlastKing’s shot-blast machines are capable of a high abrasive shot flow rate while requiring the same amount of energy as other turbines. They offer high economic efficiency as a result. Due to the fact that BlastKing can offer wear parts for high-performance turbines that are made of various materials, it is possible to adapt these too changed production requirements with little effort. To this end, it is possible to replace worn parts with carbide parts that fit perfectly. This often results in the service life increasing to ten times its previous value.

Q.18 What is the HS code for shot blasting machines and air blasting equipments?

The Harmonized System (H.S.) used for the shot blasting machine is 8479; Different countries use different sub-categories.

The Harmonized System (H.S.) used for the airblast equipment is 8424; Different countries use different sub-categories.

Troubleshooting-Frequently Asked Questions

Q.1 Why is my cycle time longer than when it was new?

- It’s out of abrasive.

- The impeller is really worn, and needs replaced.

- The blades really worn, needs replaced.

- The control cage opening is enlarged and is causing blast pattern changes, needs replaced.

- You changed the blast wheel motor and the rotation is wrong.

Q.2 I can’t get the blast wheel amperage to get above idle, why?

- The abrasive valve is closed. Check to see if the air is turned on, Make sure the abrasive valve is adjusted properly, and make sure the Mac valve is not leaking or stuck.

- The blast wheel motor is running backward. Change rotation and re-check the blast pattern.

- The abrasive valve is clogged. Empty the hopper and check.

- Screens are clogged. Clean them.

Q.3 My recovery motor overload keeps tripping, why?

- The elevator belt is loose or slipping causing this issue. Tighten it.

- The abrasive gate in the separator is restricting abrasive flow and backfilling the elevator. Raise it and tighten it down.

- The overload is malfunctioning or bad. Replace it.

- The overload is set below or bordering on the normal operating amperage. Slightly increase it by adjusting the dial.

- You have a loose wire. Check all wire connections.

- Trapped metal jamming the elevator sheaves. Clean and remove large foreign debris.

- The elevator belt makes not track properly. Adjust or replace if needed.

Q.4 Why is my blast wheel motor vibrating so badly?

- Something that rotates on the motor (impeller, blades, blocks, bare wheel, wheel hub) is out of balance. When rotating at 3600rpm it will be really apparent that you have an out-of-balance issue.

- Check all of the above items for wear. If you don’t find anything obvious then begin to remove them one at a time and find the result through a process of elimination. The last possibility is a motor bearing may have failed.

Q.5 Why am I going through more of one end liner than the other?

- The blast pattern is off or it can be a result of abrasive trailing. In other words the abrasive leaves the tip of the blade on one side of the wheel and due to the high rate of speed it can trail to the other side with momentum. It is minimal but over time it will wear one side more than the release side.

- Your blast pattern is off. Check it with a painted plate of steel.

Q.6 When should I replace my cast sheaves that are running my C-section V-belt recovery system?

Typically we recommend changing them at 80% of new, but the real concern is we need to prevent the bucket from crashing into the sheave which can cause the buckets to fall off from damage.

Q.7 How do I adjust my tumble blast mill after I install a new mill belt?

- You should properly tension it to create a ¼”-3/8” bow in the middle near the front roller. Tension the adjustment take up plates back to the factory paint line when applicable. You will need to run the mill conveyor belt for around 15 minutes or so in order to know for sure that the belt is tracking properly.

- If it is not tracking properly then check to see which direction the belt is going and tension the same side about 3/8” periodically until the belt becomes centered. It may take 3-5 minutes per-adjustment in order for enough movement to take place. The belts typically move at a rate of 12 feet per minute.

Q.8 My dust collector vacuum isn’t working like it used to, why?

- The reverse pulse system isn’t working. Check it to make sure it’s pulsing.

- The air pressure is too low and it’s not pulsing like it’s supposed to. Increase air pressure to factory specification.

- The filter cartridges are clogged. Replace them.

- The dust pipes are clogged. Inspect and clean if needed.

- There is ambient air entering the duct somehow and reducing the air volume/CFM. Seal the duct.

- The slide gate is open pulling ambient air. Close it.

- The timer board is bad. Replace it.

- Solenoid valves are bad. Replace them. • Rubber valve bladders are bad. Replace them.

Q.9 When do I change my filters cartridges?

BlastKing recommends that you change them at 5” of static. This is the point at which the filter media in the cartridge is unable to move enough air to evacuate your blast cabinet properly.

Q.10 I just installed my dust collector and it won’t reverse pulse, why?

- The electricity is not hooked up to the reverse pulse. Hook it up.

- The bolts on the bladder valve cover are loose allowing air to leak by the air pipe. Tighten them.

- The pneumatic air is off or not connected to the system. Connect it or turn it on.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!