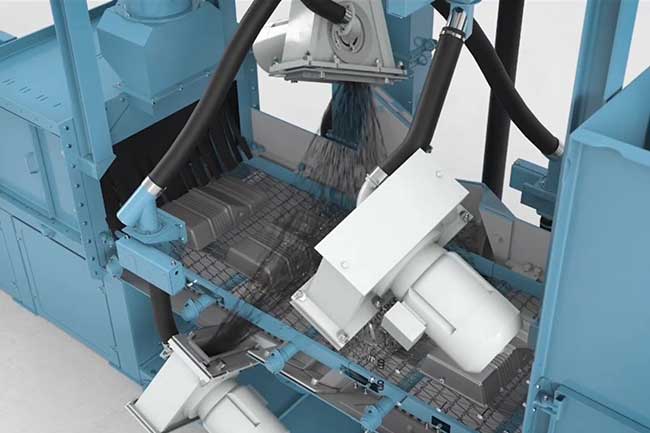

Shot Blasting Machines for Cylinders

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

The cylinder shot blasting is a surface preparation technique via the impact of high speed abrasive to clean and texture of the cylinder exterior and interior wall.

There are two cylinder shot blasting machines: external cylinder wheel blast machines and internal cylinder airblast machines.

Cylinder auto blasting machines are via the auto wheel blast to clean the outer surface of cylinders and auto air blast to clean the inner surface of cylinders, so that to remove the sticky sand, rust, oxidation, dirt, old paint, etc. The most universal type cylinder outer surface auto blasting machines are hanger type shot blasting machines and skew roll shot blasting machines.

Features

- Proven ORICA® double-disc blast wheels with the inclined layout

- Various numbers of wheels are possible

- Integrated filter unit possible – depends on machine size

- abrasive removal device

- Automatic PLC control

- Workpiece recognition

- Blasting cylinders up to 300 cylinders/hour

Applications

For the treatment of gas cylinders, LPG cylinders, oxygen bottles, etc.

- Removal of sticky sand and welding slag

- Corrosion removal

- Old paint stripping

- Rust and heat scale removal

- Increases the fatigue strength and corrosion resistance

- Prolongs the service life of the cylinder

Key Benefits

Highest Performance Cylinder Blasting Machines

There are two cylinder shot blasting machines: external cylinder wheel blast machines and internal cylinder airblast machines.

The exterior cylinder blast machines use the airless blast wheel to clean the outer surface of cylinders; the internal cylinder airblast machines via high-pressure air to accelerate the blasting media and then throw them at the interior wall surface of the cylinder to clean.

The external cylinder auto shot blasters use highly efficient and powerful blasting turbines to accelerate the blasting media and then throw the high-speed abrasive stream to the exterior surface of cylinders.

The whole blast processing will remove sticky sand, rust layer, welding slag, oxide, debris, et cetera to get a fine and smooth surface. It improves the adhesion of paint film on the steel surface, increases the cylinder’s fatigue strength and corrosion resistance, improves the inner quality of the cylinder, and prolongs its service life.

Working Video

Basic Specification

Cylinder Shot Blaster with Skew Roll

| Type | SR 20C | SR60C | SR60S |

|---|---|---|---|

| Maxi. Pipes diameter (mm) | 200 | 600 | 600 |

| Work speed (m/min) | 0.5-2 | 0.5-4 | 2-8 |

| Number of blast wheels | 2/3 | 3/4 | 3/4/5/6 |

| Power per blast wheel (kW) | 7.5/11/15/18.5 | 7.5/11/15/18.5 | 7.5/11/15/18.5/22 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Cylinder Shot Blaster with Spinner Hanger

| Machine Type | HB7/12 | HB10/16 | HB12/18 | HB14/22 | HB16/23 | HB18/25 | HB30/30 | |

|---|---|---|---|---|---|---|---|---|

| Max. diameter per cluster(mm) | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 3000 | |

| max. height per cluster(mm) | 1200 | 1600 | 2000 | 2200 | 2300 | 2500 | 3000 | |

| Max. weight per cluster(kg) | 600 | 800 | 1000 | 2000 | 3000 | 5000 | 10000 | |

| No. of wheelsx Power(kw) | 2x 7.5 | 2x 7.5/11 | 2x11/15 | 3x 7.5/11/15 | 3x 7.5/11/15 | 4x 7.5/11/15 | 5x7.5/11/15 | |

| Foundation pit | no | no | no | no | yes | yes | yes |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Cylinder Shot Blaster with Overhead Rail Conveyor

| Type | HT12-5/4R | HT12-5/8R | HT12-5/12R |

|---|---|---|---|

| Entrance size(H*W) (mm) | 1200*500 | 1200*500 | 1500 |

| Number of blast wheels | 4 | 8 | 12 |

| Power per blast wheel (kW) | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 |

| Cylinder Blasting quantity (piece/Min.) | 20-30 | 30-40 | 60-100 |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!

Call us today at +86 135 8931 7685