Aluminum Profile Blasting Machines

BlastKing is a world leader in surface preparation technology, offers a complete range of surface preparation technologies, parts and services and stands ready to improve our customers’ productivity and profitability.

Aluminum profile shot blasting is a technique of superficial treatment by the impact that can achieve a remarkable degree of cleaning and simultaneously a correct surface finishing.

- Possibility of decreasing or increasing the speed of impact of the abrasive.

- Allows adjusting conveniently the roughness obtained in the process.

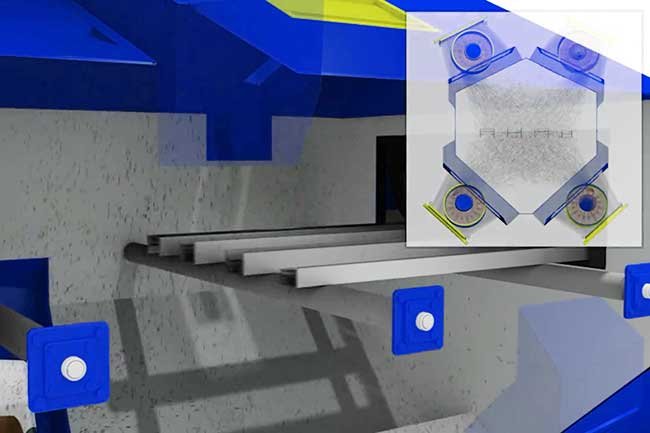

- Roller conveyor that allows processing several profiles simultaneously.

- Use of Vulkan-Inox GmbH stainless steel shot for not contaminating the profiles with rests of carbon, avoiding future oxidation.

- Blast cleaning is a process of non-polluting mechanical scaling.

Advantages

- Fast turnover of the initial investment (between 1 and 3 years)

- Recovery of profiles that are out of standard

- Recovery of second selection materials.

- Homogenization of surfaces.

- Elimination of superficial stripes because of a failure of the extrusion mold or defects caused while handling the profiles.

- Elimination of superficial stains.

- Possibility of controlling the final roughness of the profile according to the results wished.

Low operative cost

- 1.5 Kilos of consumption of stainless shot per ton of anodized profile.

- Depending on the bath’s temperature and the concentration of caustic soda used in the process, it can reduce the time of the alkaline bath to 85 %.

- Less chemical material was used (caustic soda and sulfuric acid).

- Less workforce.

- Higher lifetime of extrusion mold.

- The equipment is easy to operate and does not require specialized personnel.

Key Benefits

Aluminum Profile Blast Machines

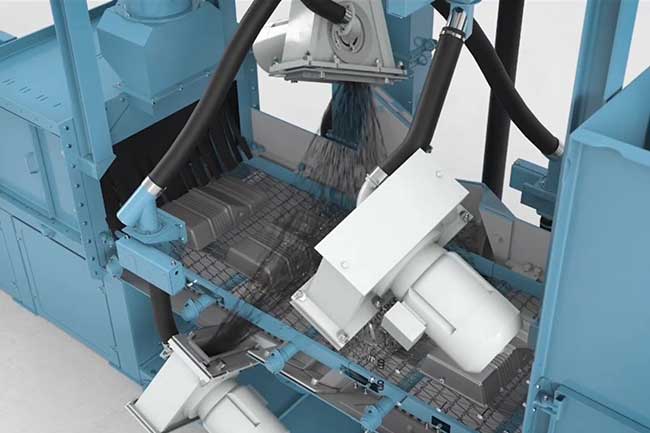

BlastKing has developed a line of equipment for continuous shot blasting of aluminum profiles previous to the anodizing process.

The centrifugal turbines accelerate the blasting media to a speed of 80m/s and then impact them on the surface of aluminium profiles. The shot-blasting is the most economical method among the current surface preparation processes that do not pollute the environment.

The functioning of the shot-blasting turbines is similar to a centrifugal pump. The shot-blasting machines for aluminum profiles use multiple turbines positioned so that the abrasive reaches all surfaces to be shot-blasted homogenously.

Working Video

Basic Specification

| TYPE | KB 600G | KB 1000G | KB 1500G | KB 2000G | KB 2500G | KB 3000G | |

|---|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 700 | 1100 | 1600 | 2200 | 2600 | 3300 | |

| Machine entrance height (mm) | 550 | 550 | 550 | 550 | 550 | 550 | |

| Work speed (m/min) | 0.5-2.3 | 0.5-2.4 | 0.5-2.3 | 0.5-2.5 | 0.5-3.0 | 0.5-2.5 | |

| Number of blast wheels | 4 | 4 | 4 | 4/6 | 6/8 | 6/8 | |

| Power per blast wheel (kw) | 7.5 | 7.5/11 | 11/15 | 11/15 | 11/15/18.5 | 11/15/18.5 | |

| Roller pitch (mm) | 800 | 650 | 650 | 800 | 800 | 800 | |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

- The technical data is not binding and may be subject to change.

- Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Get A Strong Partner at Your Side Now!

Consult your dedicated surface preparation equipment experts to make your business succeed!